What is Stainless Steel Wire Rope and How is it Used?

Stainless steel wire rope is a versatile material used in various industries. Its strength and durability make it ideal for lifting and rigging applications. Often found in construction, marine, and manufacturing sectors, this wire rope typically consists of multiple strands twisted together. It provides excellent resistance to corrosion, making it suitable for outdoor use.

Many industries rely heavily on stainless steel wire rope. For instance, cranes and elevators depend on this material for safe and effective operation. However, not all stainless steel wire rope is created equal. Various grades exist, each with its specific properties. Choosing the right grade can be challenging and requires careful consideration.

Despite its advantages, stainless steel wire rope can have its flaws. It may suffer from wear and tear over time, demanding regular inspection. Understanding these limitations is crucial for ensuring safety and performance. In the end, making informed decisions about stainless steel wire rope significantly impacts efficiency and functionality in different environments.

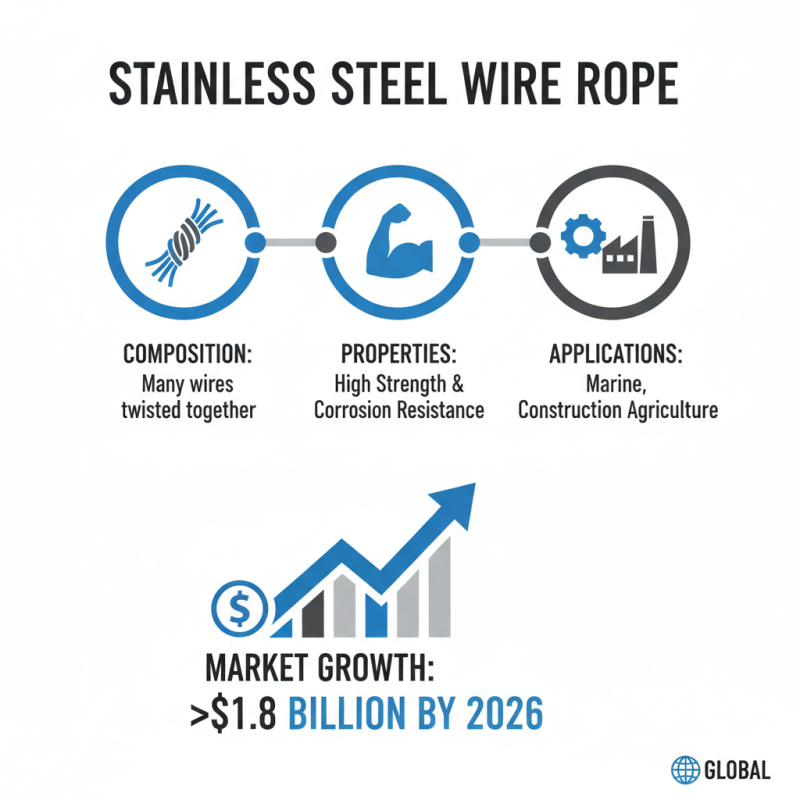

What is Stainless Steel Wire Rope?

Stainless steel wire rope is a versatile material used in various industries. Composed of numerous stainless steel wires twisted together, it boasts high tensile strength and corrosion resistance. This makes it ideal for applications in harsh environments, such as marine, construction, or agriculture. According to industry reports, the global stainless steel wire rope market is expected to reach over $1.8 billion by 2026, indicating its growing importance.

The construction industry widely uses stainless steel wire rope for lifting and supporting structures. Its lightweight yet robust nature allows easy handling while ensuring safety. Applications can range from cranes to bridges. Interestingly, a study found that while stainless steel wire rope often outperforms other materials, it can still show signs of wear over time. Factors such as extreme weather or improper installation can lead to premature failure.

In addition, the marine sector relies heavily on stainless steel wire rope for mooring and anchoring. It maintains structural integrity even in saltwater environments. Yet, not all users understand the importance of regular inspections. Neglecting maintenance can result in deterioration, which is sometimes overlooked until it's too late. Understanding these aspects is crucial for safe and effective use.

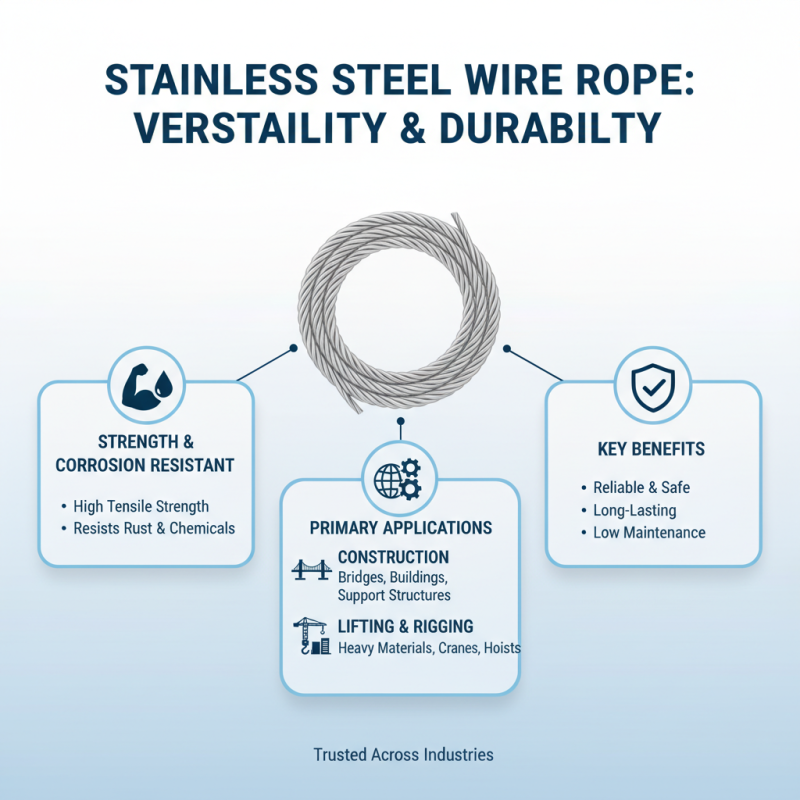

Key Properties and Advantages of Stainless Steel Wire Rope

Stainless steel wire rope is a versatile material often used in various industries. Its key properties make it an ideal choice for demanding applications. This type of wire rope is highly resistant to corrosion, making it suitable for marine environments. It maintains its strength and durability over time, even in harsh conditions.

One significant advantage is its high tensile strength. Stainless steel wire rope can bear heavy loads without breaking. Additionally, it offers flexibility, making it easier to handle. The rope can be formed into various shapes, allowing for diverse applications. However, it's crucial to note that while it's strong, improper usage can lead to failures. Regular inspection for wear and tear is essential to ensure safety.

Moreover, stainless steel wire rope is aesthetically pleasing, often used in architecture and design. The shiny finish adds a modern touch to structures. Yet, not everyone considers the maintenance required to keep it looking good. Environmental factors can affect its appearance over time. Understanding both its strengths and limitations helps in making better choices.

Usage and Properties of Stainless Steel Wire Rope

Common Applications of Stainless Steel Wire Rope in Various Industries

Stainless steel wire rope is versatile and durable. It finds applications across various industries due to its strength and resistance to corrosion. In construction, it supports structures like bridges and buildings. The wire rope aids in lifting heavy materials, providing safety and reliability.

In marine environments, stainless steel wire rope is essential. It’s used for mooring boats and securing docks. Rust resistance is crucial here, as exposure to saltwater can degrade other materials quickly. The wire rope also supports rigging and anchorage systems, which are vital for safety in sailing and shipping.

In the automotive industry, stainless steel wire rope is used in brake cables and suspension systems. These applications require strong, flexible materials to ensure performance and safety. However, the wire rope can wear over time. Regular inspections are necessary to prevent failures. It's essential to balance functionality with maintenance to ensure long-lasting use.

How to Choose the Right Stainless Steel Wire Rope for Your Needs

Choosing the right stainless steel wire rope involves several key factors. First, consider the diameter of the wire. It directly affects the strength and flexibility. A thicker rope can bear heavier loads but may be less flexible in tight spaces. Conversely, a thinner rope may be easier to handle but not suitable for high-stress applications.

Next, think about the type of stainless steel used. There are different grades, each with unique properties. For instance, some resist corrosion better, while others offer more strength. It’s not always easy to choose. You may end up with a rope that doesn’t fit your specific needs. Always assess the environment where the rope will be used. Exposure to harsh chemicals or saltwater can dramatically affect performance.

Lastly, consider the construction of the wire rope. Different braids or strands offer varying benefits. A 7x19 construction, for example, provides good flexibility and strength. However, it may not be as durable as other designs. Take your time evaluating these options, as picking the wrong rope can lead to failure. This could result in costly repairs or unsafe conditions. Aim to find a balance that suits your application.

Maintenance and Care Tips for Stainless Steel Wire Rope

Stainless steel wire rope is essential in various applications, from construction to outdoor rigging. Proper maintenance can enhance its longevity and performance. Here are some tips for caring for your stainless steel wire rope.

Keep your wire rope clean and free from debris. Dirt can cause corrosion over time. Regularly inspect it for any signs of wear. Look for fraying or broken strands. Small issues can quickly lead to larger problems.

Lubrication is critical. Apply a suitable lubricant periodically to reduce friction. This helps maintain flexibility and reduces wear. Avoid using too much lubricant, as it can trap dirt.

Lastly, store your wire rope correctly. Keep it in a dry, cool area away from direct sunlight. Improper storage can weaken the rope and lead to premature failure. By following these simple tips, you can ensure your stainless steel wire rope remains in good condition.

Related Posts

-

Top 10 Tips for Choosing the Right Stainless Steel Wire Rope for Your Projects

-

The Science Behind Stainless Mesh and Its Impact on Modern Industries

-

How to Install Cable Railing for Your Deck or Balcony Like a Pro

-

How to Install a Cable Fence for Your Property in Easy Steps

-

How to Choose the Right Steel Cable for Your Project Needs

-

The Ultimate Guide to Installing Steel Cable Railing for Your Home Design