Exploring the Versatility of Wire Rope: Applications, Benefits, and Care Tips

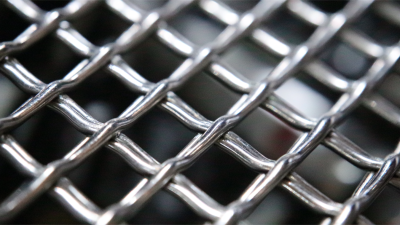

Wire rope is a remarkable and versatile material that plays a crucial role in a variety of industries, ranging from

construction and mining to

marine and aerospace. Comprising

multiple strands of steel wire twisted together, wire rope combines

strength, flexibility, and durability, making it an ideal choice for various applications

such as lifting heavy loads, rigging, and towing. Its unique properties not only enhance performance but also

provide safety and reliability in demanding environments. In this exploration of wire rope, we will delve into

its diverse applications, highlight the benefits it offers over other materials, and provide essential care

tips to ensure longevity and optimal performance. Understanding the

multifaceted nature of wire rope empowers users to make informed

decisions for their specific needs, ultimately maximizing efficiency and effectiveness in their operations.

Wire rope is a remarkable and versatile material that plays a crucial role in a variety of industries, ranging from

construction and mining to

marine and aerospace. Comprising

multiple strands of steel wire twisted together, wire rope combines

strength, flexibility, and durability, making it an ideal choice for various applications

such as lifting heavy loads, rigging, and towing. Its unique properties not only enhance performance but also

provide safety and reliability in demanding environments. In this exploration of wire rope, we will delve into

its diverse applications, highlight the benefits it offers over other materials, and provide essential care

tips to ensure longevity and optimal performance. Understanding the

multifaceted nature of wire rope empowers users to make informed

decisions for their specific needs, ultimately maximizing efficiency and effectiveness in their operations.

Applications of Wire Rope in Various Industries: A Comprehensive Overview

Wire rope is a crucial element across numerous industries, renowned for its strength, flexibility, and durability. In the construction sector, wire rope is pivotal for hoisting and hauling heavy materials, ensuring safety and efficiency on job sites. The marine industry also heavily relies on wire rope for anchoring and mooring purposes, where its corrosion resistance plays a significant role in its effectiveness. Additionally, in the automotive field, wire rope is utilized in various applications, from soft top mechanisms to suspension systems, showcasing its versatility.

Given the projected growth of the global steel wire market, which is expected to reach USD 123.23 billion by 2031, the demand for wire rope is anticipated to escalate. This increase can be attributed to the rising automotive production and advancements in manufacturing technologies. Moreover, ongoing research has highlighted innovations in materials and applications, with developments such as corrosion-resistant coatings and stronger composite materials. These advancements not only enhance the performance of wire rope but also extend its lifecycle, ensuring that industries can rely on it for their critical operations.

Key Benefits of Using Wire Rope: Strength, Durability, and Flexibility

Wire rope has cemented its place across various industries due to its key benefits: strength, durability, and flexibility. According to the International Wire and Cable Symposium, wire rope can handle tensile strengths ranging from 100 to over 300 kN, making it suitable for heavy lifting in construction and mining applications. Its remarkable strength has led to wire rope being a cornerstone in lifting equipment, ensuring safety and reliability in operations.

Moreover, the durability of wire rope is another significant advantage. The Wire Rope Association International reported that high-quality wire ropes can endure harsh environmental conditions, including corrosion and abrasion. This longevity reduces replacement costs and downtime, allowing businesses to maintain efficient operations. Additionally, wire rope's flexibility enables it to adapt to various workloads without compromising performance. This characteristic is vital in applications such as suspension bridges and aerial lifts, where the ability to bend without breaking is crucial for structural integrity and safety. As industries continue to evolve, embracing the unique properties of wire rope can lead to enhanced productivity and safety across numerous applications.

Key Benefits of Using Wire Rope

This chart illustrates the key benefits of using wire rope, highlighting its strength, durability, and flexibility compared to standard cables.

Essential Maintenance Tips for Extending the Life of Wire Rope

Proper maintenance of wire rope is crucial for ensuring its longevity and performance across various applications. Regular visual inspections can help identify signs of wear, such as fraying, corrosion, or broken wires. By catching these issues early, users can prevent failure and enhance safety. It's also essential to check for proper lubrication; using the right type of lubricant keeps the individual wires and strands from rubbing together, which can otherwise lead to premature wear.

Moreover, environmental factors can significantly affect wire rope durability. Keeping the rope dry and free from debris is vital, especially in harsh conditions. A protective cover can shield the wire rope from UV rays and extreme weather, while periodic cleaning removes contaminants that can cause corrosion. Following manufacturer guidelines for load limits and operational practices will also contribute to the wire rope's lifespan, ensuring it remains dependable for heavy-duty tasks. Adhering to these essential maintenance tips can significantly extend the life of wire rope and guarantee safety and reliability in its various uses.

Comparative Analysis: Wire Rope vs. Other Lifting Solutions

The wire rope industry has witnessed notable growth, particularly in the construction and mining sectors, driven by an increasing demand for reliable lifting solutions. A comparative analysis of wire ropes versus other lifting solutions highlights wire ropes' advantages, including enhanced durability, flexibility, and load capacity. According to a recent market outlook report, the wire rope for cranes market is anticipated to expand significantly, reflecting the industry's transition towards automated systems that require high-performance lifting equipment.

When considering the maintenance and safety of wire ropes, especially in mining applications, regular inspections and Nondestructive Testing (NDT) are critical. Using advanced techniques, such as magnetic sensors, can effectively assess the wear and fatigue of wire ropes, ensuring miner safety. Regular monitoring not only extends the lifespan of the equipment but also minimizes the risk of accidents, proving the value of investing in state-of-the-art testing solutions.

Tips for Wire Rope Care:

- Always perform routine inspections to identify signs of wear and corrosion early.

- Implement proper lubrication practices to reduce friction and improve the longevity of wire ropes.

- Ensure that operators are trained in correct handling techniques to prevent unnecessary strain and damage during usage.

Innovative Uses of Wire Rope in Modern Engineering Projects

Wire rope has become an essential component in various modern engineering projects, showcasing its innovative applications across multiple industries. One notable use is in construction, where wire ropes serve as lifelines for workers and are integral to lifting heavy materials. Their high tensile strength enables cranes and hoists to operate safely and efficiently, ensuring that construction sites can maintain a steady workflow while adhering to safety regulations. This adaptability allows engineers to design and implement complex structures with confidence in the materials they utilize.

In addition to construction, wire ropes find their place in the transportation sector, specifically in cable cars and ski lifts. These systems harness the reliability of wire ropes to transport people and goods in challenging terrains, demonstrating their capability to support significant loads over long distances. Furthermore, wire ropes are increasingly used in renewable energy projects, such as wind turbines, where they assist in the lifting and securing of massive turbine components during installation. The versatility of wire rope truly shines as it continues to evolve alongside technological advancements, influencing the future of engineering applications.

Exploring the Versatility of Wire Rope: Applications, Benefits, and Care Tips

| Application | Benefits | Care Tips |

|---|---|---|

| Construction Lifting | High strength and durability | Inspect regularly for wear |

| Marine Applications | Corrosion-resistant options available | Clean with fresh water after use |

| Mining Operations | Excellent load-bearing capacity | Lubricate to prevent rust |

| Telecommunications | Supports aerial cable deployment | Check for fraying before use |

| Agricultural Equipment | Reliable for hauling and lifting | Store in a dry area |

Related Posts

-

Transform Your Space with Stylish Cable Railing Kits for Modern Home Designs

-

Exploring Growth Opportunities for Stainless Steel Cable Railing Systems at the 138th Canton Fair 2025

-

The Ultimate Guide to Choosing the Right Cable Stair Railing for Your Home Decor

-

Exploring Stainless Steel Mesh Innovations at the 138th Canton Fair 2025: Industry Trends and Insights

-

Revolutionizing Safety: The Impact of Cable Handrail Systems on Modern Architecture

-

Exploring Cable Railing Innovations at the 138th Canton Fair 2025 in China