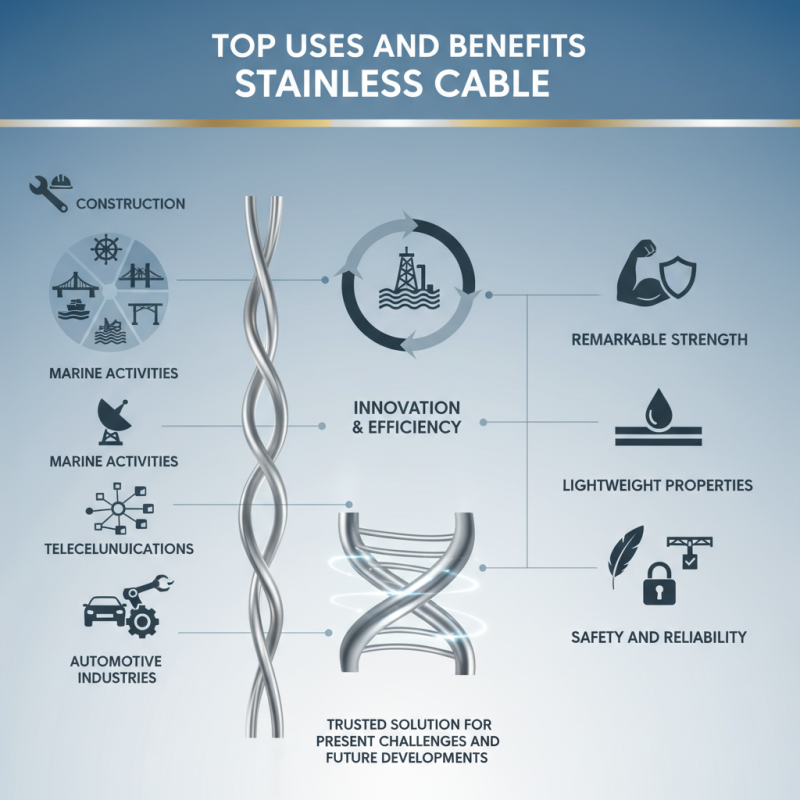

Top Uses and Benefits of Stainless Cable in Various Industries

In the rapidly evolving industrial landscape, the versatility and durability of stainless cable have made it an essential resource across various sectors. Recognized for its remarkable strength, corrosion resistance, and lightweight properties, stainless cable is increasingly becoming the preferred choice for applications ranging from construction and marine activities to telecommunications and automotive industries. As businesses prioritize safety and reliability, the demand for stainless cable is on the rise, showcasing its significance in modern engineering and infrastructure development.

The applications of stainless cable are as diverse as the industries it serves. In construction, it is utilized for structural support and fixtures, enhancing safety and longevity. In marine environments, its resistance to rust and saltwater degradation ensures that projects remain intact under challenging conditions. Meanwhile, the telecommunications industry relies on stainless cable for its ability to withstand high stress and environmental changes, facilitating effective communication networks. These examples highlight not just the practicality of stainless cable, but also its critical role in fostering innovation and efficiency across sectors.

As we delve deeper into the top uses and benefits of stainless cable, it becomes clear that this robust material is not merely a component but a cornerstone in the advancement of various industries. Understanding its applications will shed light on why it continues to be a trusted solution for both present challenges and future developments.

Applications of Stainless Cable in Construction and Architecture

Stainless cable has become an integral component in construction and architecture, thanks to its exceptional durability, corrosion resistance, and aesthetic appeal. In a 2021 report by the International Institute of Stainless Steel, it was noted that the demand for stainless steel products in construction increased by approximately 6% annually, primarily fueled by the growing trend of using stainless cable for structural applications. Architects and engineers are increasingly turning to stainless cable for tensioning systems in buildings, bridges, and large public structures where strength and safety are paramount.

One key application of stainless cable in construction is in the design of cable-stayed bridges and reinforced structures. According to a study published by the Construction Industry Institute, adopting stainless cable in bridge engineering has proven to extend the lifespan of structures by up to 50% due to its resistance to environmental stressors. This not only ensures safety but also leads to significant cost savings over time due to reduced maintenance needs.

Tips: When selecting stainless cable for construction projects, ensure that the grade of stainless steel is suitable for the specific environmental conditions it will face. Different grades offer varying levels of corrosion resistance, which can be crucial for projects located in coastal or industrial areas. Additionally, proper installation techniques are essential to maximize the performance and longevity of stainless cable systems.

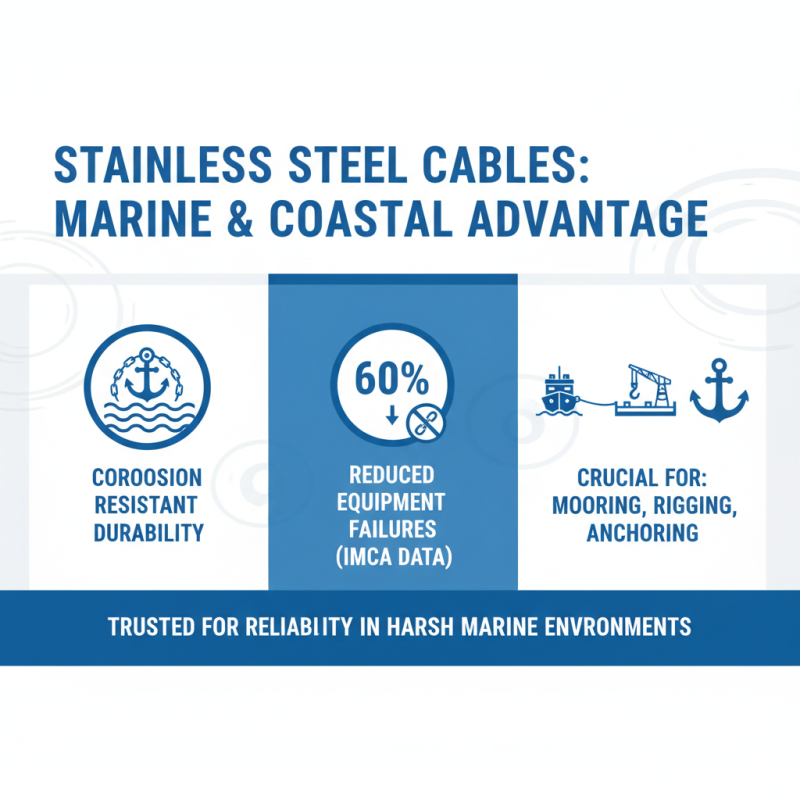

Advantages of Stainless Cable in Marine and Coastal Industries

The marine and coastal industries have long recognized stainless cables as a vital component due to their superior resistance to corrosion and durability in harsh environments. According to the International Marine Contractors Association (IMCA) data, over 60% of marine equipment failures are linked to material degradation, which is significantly minimized by using stainless steel cables. This is particularly crucial in applications such as mooring, rigging, and anchoring, where reliance on the integrity of the cable is paramount.

Stainless cables, especially those made from marine-grade stainless steel, exhibit low maintenance requirements and extended lifespan, often lasting 15 years or more under challenging coastal conditions. The National Association of Steel Wire Rope Manufacturers (NASWRM) highlights that stainless cables can endure exposure to saltwater, chemicals, and UV radiation, making them ideal for offshore installations and coastal infrastructure. This resilience not only enhances safety but also leads to substantial cost savings over time, making stainless cables an indispensable asset in the marine sector.

The Role of Stainless Cable in Transportation and Infrastructure

Stainless cable has become an essential component in transportation and infrastructure due to its exceptional properties, such as corrosion resistance, durability, and strength. These attributes are particularly vital in applications like bridge construction, where cables must withstand not only tensile stress but also the elements. According to a report by Research and Markets, the global wire rope market, which includes stainless cables, is projected to grow at a CAGR of 4.5% from 2022 to 2027, reflecting the increasing demand in these critical sectors.

In transportation systems, stainless cables are commonly used in cable-stayed and suspension bridges, where they provide the necessary support for loads and ensure structural integrity. The International Association for Bridge and Structural Engineering has emphasized that the use of stainless steel cables significantly reduces maintenance costs due to their resistance to rust and environmental degradation, often extending the lifespan of the infrastructure by several decades. Additionally, as urban areas continue to expand, incorporating stainless cables into public transport and safety systems, such as elevated railways and pedestrian bridges, showcases their importance in enhancing public safety and accessibility.

In transportation systems, stainless cables are commonly used in cable-stayed and suspension bridges, where they provide the necessary support for loads and ensure structural integrity. The International Association for Bridge and Structural Engineering has emphasized that the use of stainless steel cables significantly reduces maintenance costs due to their resistance to rust and environmental degradation, often extending the lifespan of the infrastructure by several decades. Additionally, as urban areas continue to expand, incorporating stainless cables into public transport and safety systems, such as elevated railways and pedestrian bridges, showcases their importance in enhancing public safety and accessibility.

With advancements in technology, the manufacturing of stainless cables is becoming more efficient, further promoting their use in infrastructure projects. A 2021 report from the American Society of Civil Engineers indicated that investing in stainless steel and other advanced materials could lead to a 20-30% reduction in maintenance costs over the lifecycle of constructions. This highlights not only the economic but also the strategic benefits of using stainless cables in the ongoing development and upgrading of transportation infrastructure worldwide.

With advancements in technology, the manufacturing of stainless cables is becoming more efficient, further promoting their use in infrastructure projects. A 2021 report from the American Society of Civil Engineers indicated that investing in stainless steel and other advanced materials could lead to a 20-30% reduction in maintenance costs over the lifecycle of constructions. This highlights not only the economic but also the strategic benefits of using stainless cables in the ongoing development and upgrading of transportation infrastructure worldwide.

Impact of Stainless Cable on Telecommunications and Data Networks

The telecommunications and data networks sectors have experienced significant transformations with the adoption of stainless cables. According to a report by Mordor Intelligence, the global demand for stainless steel wire and cable in telecommunications is projected to grow at a CAGR of 5.4% from 2021 to 2026. This growth can be attributed to the cables' superior resistance to corrosion and enhanced durability compared to traditional materials. Stainless cables provide a reliable solution for maintaining signal integrity across various environments, from urban settings to offshore installations, thereby ensuring efficient data transmission.

In addition to durability, stainless cables are essential for their lightweight characteristics, allowing for easier handling and installation in intricate network setups. A report from the International Telecommunication Union highlights that the global number of internet users reached 4.9 billion in 2021, indicating an urgent need for robust infrastructure to support this growing demand. Stainless cables enhance network resilience, minimize maintenance costs, and extend service life, which is crucial as telecom companies strive to expand their fiber optics and wireless networks. With 5G technology on the rise, the need for advanced, reliable cabling solutions ensures that stainless cables will play a pivotal role in the future of telecommunications and data networks.

Top Uses and Benefits of Stainless Cable in Various Industries

| Industry | Primary Use | Benefits | Impact on Telecommunications |

|---|---|---|---|

| Telecommunications | Signal Transmission | Corrosion Resistance, Durability | Enhanced data integrity and speed |

| Data Networks | Cable Management | Low Maintenance, Long Lifespan | Increased network reliability and uptime |

| Construction | Structural Support | Strength, Resilience | Supports telecommunication tower stability |

| Marine | Anchoring Systems | Resistance to Saltwater Corrosion | Reliable communication in marine environments |

| Utilities | Power Line Suspension | High Tensile Strength | Improved data and energy transmission |

Benefits of Using Stainless Cable in Manufacturing and Industrial Settings

Stainless cable is an essential component in manufacturing and industrial settings, offering a multitude of benefits that enhance efficiency and safety. One of the primary advantages of using stainless cable is its exceptional resistance to corrosion and rust. This property is particularly vital in environments where exposure to moisture and chemicals is common, such as in food processing plants and chemical manufacturing facilities. By reducing the risk of material degradation, stainless cables ensure a longer lifespan and reduce maintenance costs, allowing manufacturers to operate with greater reliability.

In addition to corrosion resistance, stainless cables boast high tensile strength, making them ideal for heavy-duty applications. Their robustness enables them to support heavy loads and withstand the stresses encountered in harsh industrial conditions. This strength translates into improved safety for workers, as the likelihood of cable failure is significantly diminished. Moreover, stainless cables are versatile and can be used in various applications ranging from lifting and rigging to securing equipment, making them an indispensable resource in numerous sectors, including construction, marine, and automotive industries. These unique properties of stainless cable ultimately contribute to a more efficient and safer manufacturing environment.

Related Posts

-

2025 Top Stainless Steel Cable Uses Benefits and Buying Guide

-

Why Choose Stainless Mesh for Your Next Project? Key Benefits Explained

-

How to Choose the Best Wire Railing for Your Outdoor Spaces: 2023 Expert Guide

-

What is a Cable Railing System for Decks and How to Choose the Best One

-

Exploring the Benefits of Wire Deck Railing: A Comprehensive Guide to Safety and Aesthetics

-

10 Reasons Why Steel Cable Railing is the Best Choice for Modern Decks: Safety, Durability & Style Insights