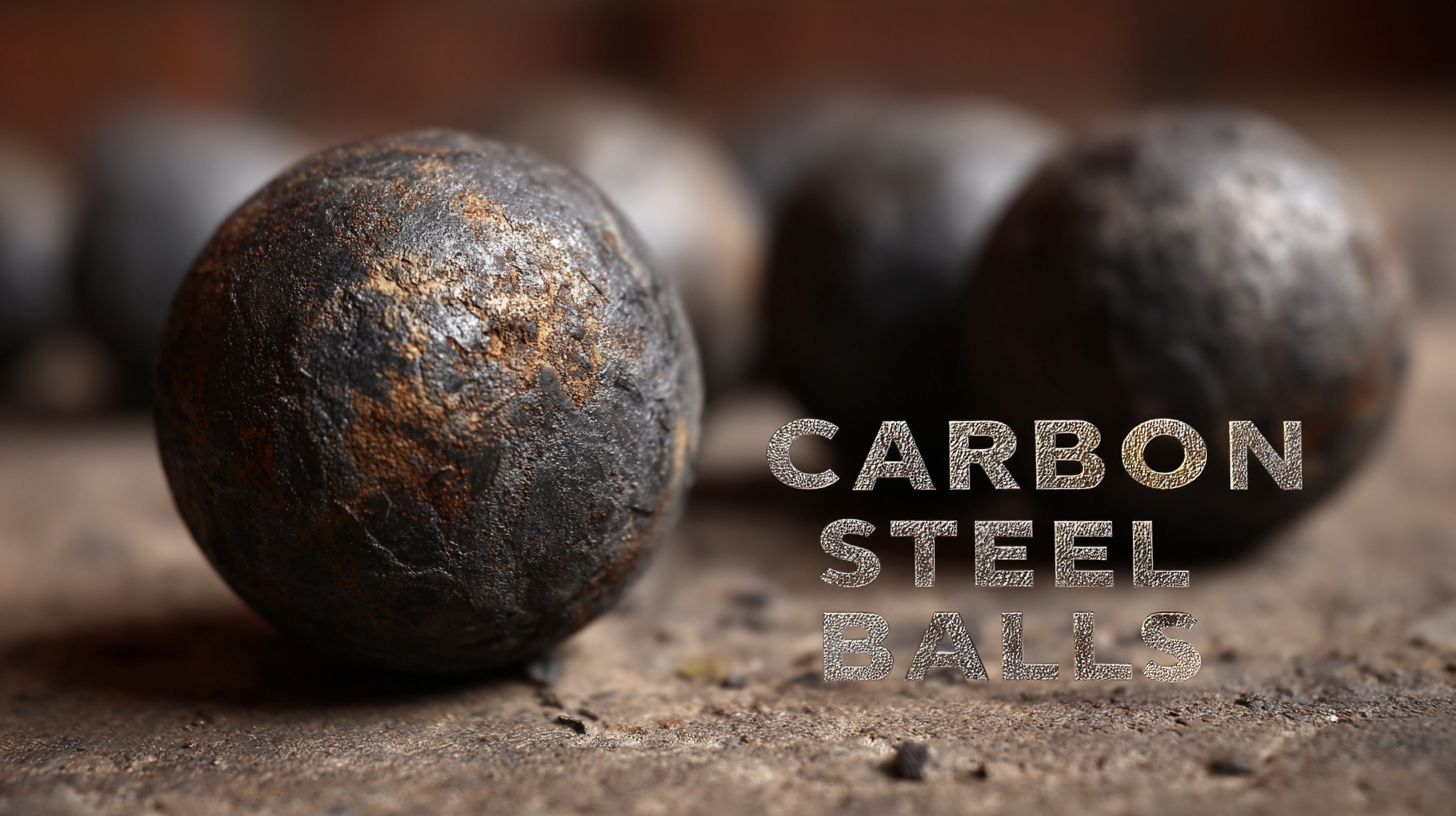

In today's fast-paced industrial landscape, the quest for enhanced efficiency has never been more critical. Among the myriad of components that contribute to operational excellence, the Carbon Steel Ball stands out as an unsung hero. Renowned for its durability and versatility, this exceptional material is increasingly becoming the go-to choice for various applications across industries. Chinese manufacturers have emerged as leaders in this domain, not only by showcasing the superior quality of their carbon steel balls but also by establishing a robust export prowess that caters to global demands.

As we delve into the unparalleled advantages offered by the best carbon steel balls, it becomes evident that their superior performance can unlock significant improvements in productivity and cost-effectiveness for businesses worldwide. Embracing this remarkable product is not just about enhancing efficiency; it's about aligning with the future of industrial manufacturing excellence.

Carbon steel balls are increasingly recognized for their outstanding advantages across various industries, driving operational efficiency and enhancing performance. According to a report by Grand View Research, the global market for steel balls is expected to exceed $2.1 billion by 2025, highlighting the growing reliance on these components in manufacturing and mechanical applications. The superior hardness and wear resistance of carbon steel balls make them ideal for use in bearings, automotive applications, and precision machinery.

In industries such as aerospace and automotive, the use of high-quality carbon steel balls eliminates frictional losses, thereby improving energy efficiency. A study published in the Journal of Materials Science indicates that the application of carbon steel balls in ball bearings can result in a reduction of energy consumption by 10-15%. Additionally, these balls have a higher load-bearing capacity, which translates to longer service life and reduced maintenance costs. This enhances overall productivity and positions businesses to meet increasing demands while still adhering to operational budgets. The integration of carbon steel balls not only boosts performance but also establishes a reliable foundation for innovation in industrial processes.

In today’s competitive industrial landscape, controlling operating costs is paramount for maintaining profitability. One effective way to achieve this is by utilizing the best carbon steel balls. These robust components play a crucial role in various applications, from reducing friction in machinery to optimizing performance in moving parts. By minimizing wear and tear, carbon steel balls can significantly extend the lifespan of machinery, leading to lower maintenance costs and downtime.

Tip 1: When selecting carbon steel balls, ensure they meet the necessary quality standards specific to your industry. High-quality balls not only improve efficiency but also reduce the frequency of replacements, which can lead to substantial long-term savings.

Moreover, the use of carbon steel balls can enhance energy efficiency. Their precise roundness and hardness allow for smoother operations, thus requiring less energy to function. This can translate into a substantial reduction in energy bills over time.

Tip 2: Regularly monitor the condition of carbon steel balls in your equipment. Implementing a routine maintenance schedule can help identify signs of wear early, allowing for timely replacements that prevent more significant issues and unexpected costs.

When considering the best materials for industrial applications, carbon steel balls stand out due to their exceptional properties and advantages over alternatives. Compared to ceramic or plastic balls, carbon steel balls provide significantly greater strength and durability. This is crucial in high-load environments where resistance to wear and deformation is essential for maintaining operational efficiency. Their hardness ensures they can withstand high pressures and impacts, making them ideal for heavy machinery and equipment.

Moreover, carbon steel balls exhibit superior precision in size and shape retention, which is vital for applications in bearings and other components where accuracy is critical. In contrast, alternatives like plastic balls may deform under stress, leading to failures and increased maintenance costs. Additionally, carbon steel balls often come with lower friction coefficients than their ceramic counterparts, contributing to smoother operation and reduced energy consumption. Overall, the choice between carbon steel balls and their alternatives should be clear for industries aiming to maximize efficiency and reliability.

The landscape of carbon steel ball manufacturing is evolving rapidly, driven by advancements in technology and increasing demand for improved performance across industries. As manufacturers embrace innovative techniques such as precision forging and CNC machining, the quality and efficiency of carbon steel balls are set to reach new heights. This shift not only enhances production capabilities but also allows for tailored solutions that meet the specific needs of various applications.

Tip: When selecting carbon steel balls, consider the specific requirements of your project, such as load-bearing capacities and environmental factors, to ensure optimal performance and longevity.

Emerging trends indicate a growing focus on sustainability within the carbon steel ball industry. Many manufacturers are exploring eco-friendly materials and processes to reduce their carbon footprint while maintaining high standards of quality and durability. Additionally, advancements in surface treatments and coatings will lead to enhanced corrosion resistance, further extending the lifespan of these crucial components in machinery and automotive applications.

Tip: Stay informed about the developments in carbon steel ball coatings to leverage the latest innovations for improving the durability of your products. By anticipating these trends, businesses can not only enhance their operational efficiency but also stay competitive in an ever-evolving market.

When it comes to maximizing the longevity of carbon steel balls in industrial applications, proper maintenance is crucial. These robust components offer high performance and durability, but they also require attention to retain their optimal condition. Regular inspections can help identify any early signs of wear or corrosion. Ensure that the carbon steel balls are free from debris and contaminants, as these can lead to premature failure.

Another key tip is to lubricate the carbon steel balls appropriately. Using the right type of lubrication not only reduces friction but also helps prevent rust formation. Depending on the environment in which they are used, different lubricants may be required to ensure seamless operation. It's important to follow the manufacturer’s guidelines for lubrication frequency and application methods.

Lastly, consider the storage conditions for carbon steel balls when they are not in use. Keeping them in a dry and controlled environment can significantly reduce the risk of oxidation. Implementing these maintenance tips can extend the lifespan of carbon steel balls and ensure their continued efficiency in your operations.

This bar chart illustrates the key advantages of using carbon steel balls in industry. Each advantage is rated on a scale from 1 to 10, highlighting their significant contributions to efficiency and performance in various applications.