In the world of industrial applications, the right components can make all the difference in operational efficiency and product performance. Among these critical components, bearing steel balls play a pivotal role in enabling smooth motion and reducing friction in various machinery and equipment. This ultimate guide is designed to help you navigate the complexities of sourcing the best bearing steel balls for your business needs. Whether you're involved in manufacturing, automotive, or engineering sectors, understanding the specifications, materials, and quality standards of bearing steel balls is essential for making informed purchasing decisions.

In this guide, we will cover essential factors to consider, tips for selecting the right supplier, and insights into ensuring the performance and durability of those vital steel balls, ultimately enhancing your business outcomes and operational success.

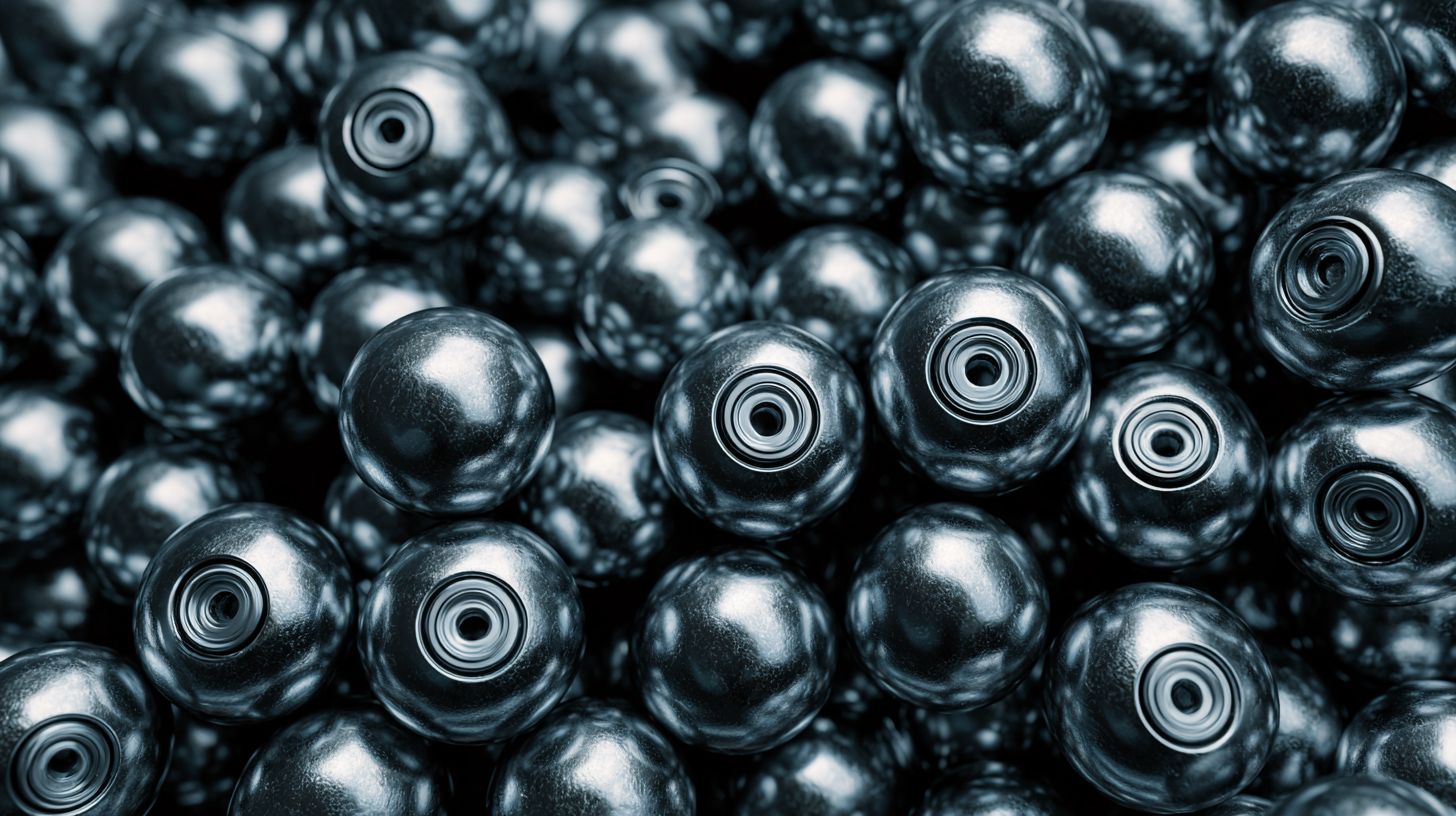

When it comes to selecting bearing steel balls for your business needs, understanding

the various types and their applications is crucial. The most common types of bearing steel balls include carbon steel,

stainless steel, and chrome steel.

Carbon steel balls are typically used in low-load applications where corrosion resistance is not a primary concern. They offer a good balance

of hardness and wear resistance, making them suitable for general-purpose applications.

On the other hand, stainless steel balls are ideal for environments where moisture or chemical exposure is a factor.

Their resistance to corrosion makes them particularly valuable in industries such as food processing and pharmaceuticals.

Chrome steel balls, known for their high hardness and superior wear resistance,

are commonly used in high-load applications, such as automotive and industrial machinery. By understanding these differences, businesses

can make informed decisions that align with their operational needs and ensure optimal performance of their equipment.

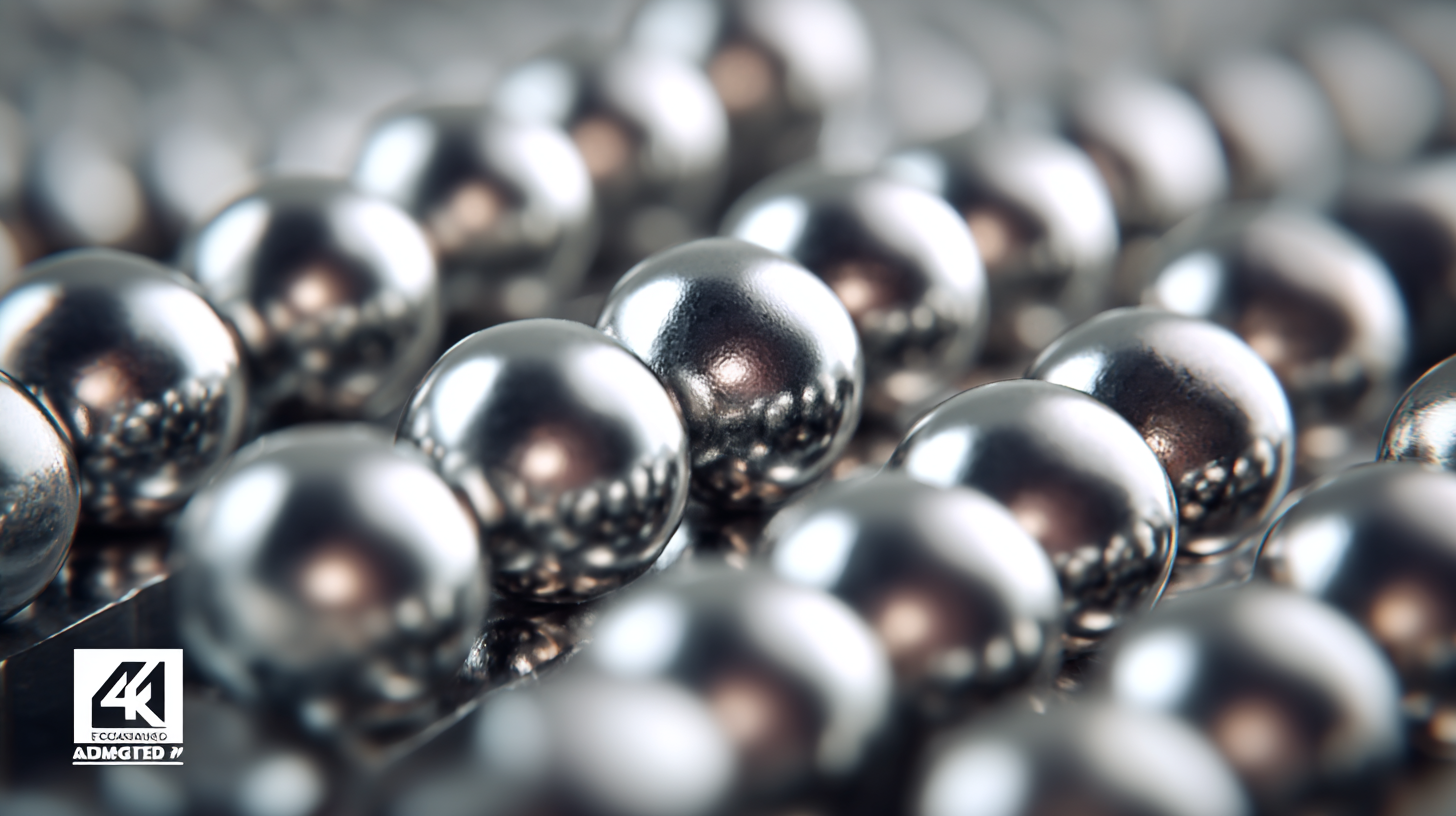

When sourcing bearing steel balls for your business, understanding the key factors that influence quality and performance is crucial. First and foremost, consider the material specifications, particularly the type of steel used, as this impacts not only durability but also overall efficiency. High-carbon chrome steel (aISI 52100) is often preferred due to its excellent wear resistance and high load-carrying capacity. Additionally, verify compliance with industry standards, such as ISO and ASTM, to ensure you receive products that are capable of meeting operational requirements.

Another significant factor is the precision and tolerances of the bearing balls. Precision levels can greatly influence the performance of your application, so choosing suppliers who utilize advanced manufacturing processes is essential. Look for options that offer different grades of precision, as this will allow you to select the most suitable product based on your specific needs. Finally, consider supplier reliability and service quality; establishing a partnership with a reputable supplier who provides consistent quality and responsive support will enhance your procurement process and overall business success.

The quality of bearing steel balls plays a crucial role in the performance and longevity of machinery. Recent advancements in manufacturing techniques have significantly improved the consistency and durability of these components. Innovations such as precision forging and heat treatment processes are at the forefront of this evolution, enabling manufacturers to produce steel balls with superior mechanical properties. Precision forging, for instance, reduces material wastage and enhances density, resulting in a more resilient product that can withstand higher loads and stresses.

Additionally, the introduction of automated quality control systems during production has revolutionized how manufacturers detect defects. By employing advanced sensors and real-time monitoring, producers can ensure that each batch of steel balls meets stringent quality standards, reducing the risk of failure in critical applications. Furthermore, the use of advanced alloys and surface treatments enhances wear resistance, providing longer-lasting solutions for industrial partners. As the industry continues to adopt these innovative techniques, businesses can expect improved performance and reliability from their bearing steel balls, ultimately leading to operational efficiencies and cost savings.

When seeking the best bearing steel ball vendors, it’s crucial to establish clear criteria for evaluation. Start by assessing the supplier's reputation in the industry; read reviews and testimonials to gauge the experiences of other businesses. A well-established company with positive feedback is likely to provide high-quality products and reliable service. Additionally, consider the supplier's certifications and standards compliance, which can indicate their commitment to quality and safety.

Tip: Always request samples before making a bulk purchase. This allows you to evaluate the steel balls' authenticity and performance before committing to a larger order.

Next, focus on the supplier's production capabilities. It’s important to ensure they can meet your specific volume and customization needs. Ask about their manufacturing processes and lead times. A responsive supplier who can adapt to your requirements demonstrates their capability to support your business growth effectively.

Tip: Establish a direct line of communication with potential suppliers. This will not only help you assess their customer service but also provide you with valuable insights into their operations and reliability.

As the demand for high-performance bearing steel balls continues to rise, it is crucial to keep an eye on future trends in production and their market implications. One significant trend is the increasing adoption of advanced manufacturing technologies like 3D printing and automation. These innovations not only streamline production processes but also enhance the precision and quality of bearing steel balls. As businesses look for suppliers, prioritizing those who invest in these technologies can lead to higher efficiency and better product outcomes.

Tip: When sourcing bearing steel balls, consider suppliers who employ state-of-the-art production techniques. This can help ensure that you receive high-quality products that meet industry standards.

Another critical trend is the growing emphasis on sustainability within the bearing steel industry. Manufacturers are increasingly focusing on eco-friendly materials and processes to reduce their carbon footprint. This shift not only aligns with global sustainability goals but also caters to businesses seeking to enhance their own environmental responsibilities. By aligning with suppliers who prioritize sustainability, companies can bolster their brand image and appeal to eco-conscious customers.

Tip: Look for suppliers who provide transparency about their sourcing and manufacturing practices. This will help you make informed decisions that support both your business needs and sustainability goals.

| Dimension (mm) | Material Grade | Surface Hardness (HRC) | Production Method | Market Price (USD per kg) | Future Trend |

|---|---|---|---|---|---|

| 3 | G25 | 61 | Cold Drawn | 23.50 | Increased automation in production |

| 5 | G10 | 64 | Cold Rolled | 30.00 | Rising demand for high precision balls |

| 7 | G25 | 60 | Tempered | 26.75 | Shift towards sustainable materials |

| 10 | G5 | 65 | Hardening | 40.00 | Technological advancements in manufacturing |

| 12 | G10 | 63 | CNC Machined | 35.50 | Growth in the automotive sector |