Top 10 Uses of Wire Rope in Various Industries Today?

In today's industrial landscape, the use of wire rope is essential across various sectors. Experts like James Thompson, a leading figure in the wire rope industry, emphasize its versatility. He has stated, "Wire rope is the backbone of industrial lifting and hauling." This highlights the critical role wire rope plays in multiple applications.

Wire rope is found in construction, mining, and maritime industries. For instance, it’s used for lifting heavy loads in construction sites. In shipping, wire rope helps secure containers on ships. The strength and durability of wire rope enhance safety measures in these environments. However, the industry faces challenges, such as wear and fatigue over time, urging a need for innovation.

Despite its advantages, some may overlook the proper maintenance of wire rope. Neglecting care can lead to failures and accidents. Users must be vigilant, ensuring their wire rope is suitable for its intended use. Ultimately, understanding the uses and limitations of wire rope is vital for safe and effective operations across industries.

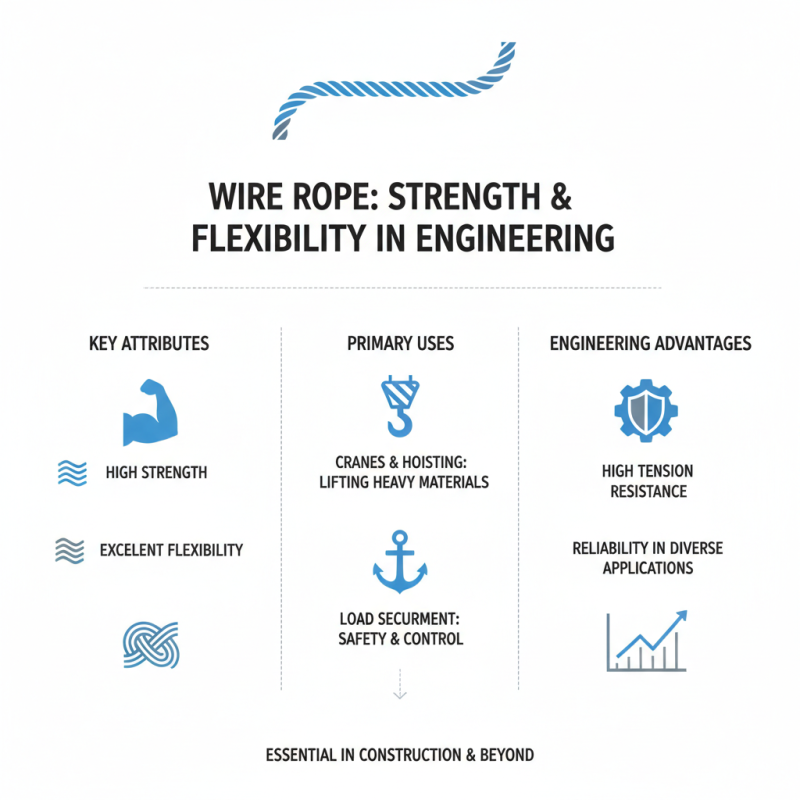

Applications of Wire Rope in Construction and Engineering Sectors

Wire rope plays a crucial role in construction and engineering sectors. It is known for its strength and flexibility. Used widely in cranes, wire ropes lift heavy materials. They secure loads efficiently, offering both safety and control. These ropes can withstand considerable tension, making them reliable in various applications.

In bridge construction, wire rope is essential. It acts as a support system for suspension bridges. Engineers rely on it to maintain structural integrity. Its durability ensures that bridges can handle environmental stress. However, proper maintenance is critical. Over time, wear and tear can compromise safety.

Additionally, wire rope is prominent in mining and drilling operations. It helps in transporting materials to the surface. Deterioration can occur in harsh environments, creating risks. It requires regular inspections to ensure functionality. Despite its advantages, there are challenges. Balancing strength with flexibility often leads to design dilemmas.

Use of Wire Rope in Maritime and Shipping Industries

Wire rope plays a crucial role in the maritime and shipping industries. It is widely used for mooring, towing, and lifting heavy loads. Its durability and strength make it ideal for securing cargo during transport. Ships rely on wire rope for reliable anchoring in rough waters. Proper usage ensures safety and efficiency.

When dealing with wire rope, inspect it regularly for wear and tear. Small frays can lead to bigger issues. Always replace damaged sections promptly. Keeping the rope clean and lubricated extends its life.

Consider the environmental impact of your operations. Marine environments can be harsh, and using strong materials minimizes waste. Responsible handling practices are essential for both safety and sustainability. Respecting these guidelines ensures the longevity of equipment and operations.

Top 10 Uses of Wire Rope in Maritime and Shipping Industries

| Application | Description | Industry Impact |

|---|---|---|

| Cargo Lifting | Used for hoisting and lowering heavy cargo from ships. | Enhances safety and efficiency in cargo handling. |

| Mooring | Secures ships in place at docks or during anchoring. | Ensures stability and security of vessels. |

| Tow Lines | Used for towing vessels and barges. | Improves maneuverability in water bodies. |

| Lifeboat Launching | Facilitates the safe launching of lifeboats during emergencies. | Critical for passenger safety and rescue operations. |

| Crane Operation | Used as part of rigging for cranes on ships and docks. | Increases operational capacity for heavy lifting. |

| Maintenance Access | Provides access to high areas for maintenance work. | Ensures timely maintenance of vessels and equipment. |

| Derrick Operations | Utilized for lifting and lowering operations on ships. | Enhances efficiency in material handling. |

| Surveying | Assists in underwater surveying and installation tasks. | Facilitates precise measurement and installation. |

| Ballast Adjustment | Helps in adjusting ballast for stability. | Maintains vessel balance and performance. |

| Anchor Handling | Used in handling and securing anchors. | Essential for safe anchoring in various conditions. |

Wire Rope Applications in Mining and Heavy Machinery Operations

Wire rope is an essential component in mining and heavy machinery operations. This sturdy material is designed to handle extreme loads and harsh environments. In mining, wire ropes are used for hoisting and lowering heavy equipment. They lift bulky loads like ore and machinery with precision. The durability of wire ropes ensures they can withstand the wear and tear of continuous use.

Another critical application is in cranes and excavators. These machines rely on wire ropes for lifting and rigging. Operators depend on the strength and reliability of wire ropes for safe operations. However, the risk of wear and fatigue over time is a constant concern. Regular inspections are vital. Failing to monitor the condition can lead to accidents, causing significant delays and safety hazards.

Furthermore, wire rope is often used in conveyors. These systems transport materials quickly and efficiently. But improper installation or maintenance can lead to breakdowns. Problems can disrupt operations and affect productivity. It's crucial to approach wire rope applications with caution and a proactive mindset. Recognizing the potential issues early can save time and resources in the long run.

Significance of Wire Rope in Transportation and Logistics

Wire rope plays a crucial role in transportation and logistics. It is used to lift, pull, and secure heavy loads across various industries. In the shipping sector, for instance, wire rope systems facilitate the loading and unloading of cargo, ensuring efficiency and safety. According to industry reports, over 60% of shipping accidents involve improper lifting techniques. This highlights the importance of using high-quality wire rope solutions.

In logistics, wire ropes provide the reliability necessary for day-to-day operations. They are key in cranes, hoists, and winches. The Global Wire Rope Market Report suggests that demand will grow by 4.5% annually through 2025. Companies should invest in regular maintenance to ensure longevity. Neglected cable systems can lead to costly downtimes.

Tip: Always inspect wire ropes for signs of wear and damage. Replace them before they fail to prevent accidents. Remember that safety should never be compromised for cost-cutting.

Another consideration is the corrosive environment of some industries. Specialized wire ropes can prevent rust and extend lifespan significantly. Companies must balance costs with safety and efficiency. Choosing the right material is essential for optimal performance.

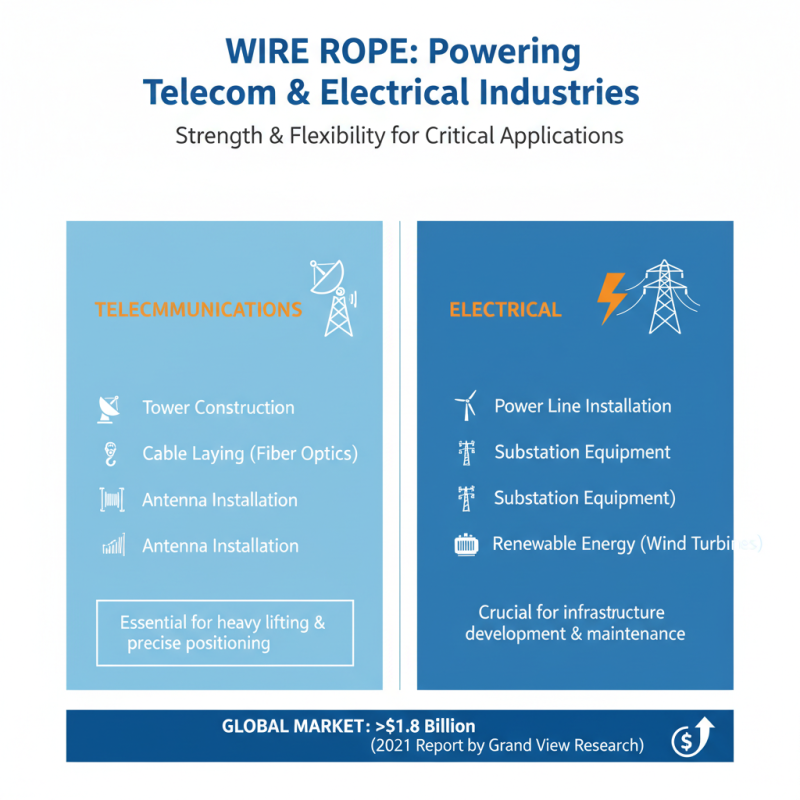

Role of Wire Rope in Telecommunications and Electrical Industries

Wire rope plays a vital role in telecommunications and electrical industries. Its strength and flexibility make it an ideal choice for heavy lifting and pulling applications. According to a report by Grand View Research, the global wire rope market size was valued at over $1.8 billion in 2021, with significant contributions from these sectors.

In telecommunications, wire rope is often used in transmission systems. It supports cables that carry vital data across long distances. The durability of wire rope is essential here. The failure of a single cable can disrupt services for millions. Furthermore, many infrastructures stress test wire ropes to ensure reliability. Yet, some manufacturers overlook these tests. The implications can be severe, impacting both companies and consumers.

The electrical industry also relies heavily on wire rope. It often assists in the installation of electrical lines and supports various overhead systems. A report from MarketsandMarkets highlights a growing demand for wire ropes in this industry, as the global energy sector expands. However, challenges arise from environmental factors. The wear and tear on wire ropes can lead to unexpected failures. Regular inspection and maintenance are indispensable, yet often neglected.

Related Posts

-

Understanding the Lifespan and Maintenance of Wire Rope for Optimal Performance and Safety

-

How to Choose the Best Wire Railing for Your Outdoor Spaces: 2023 Expert Guide

-

The Ultimate Guide to Installing Steel Cable Railing for Your Home Design

-

Top 10 Benefits of Cable Railing for Decks: Enhance Safety and Style

-

2025 Top 5 Cable Handrail Systems for Modern Home and Commercial Design

-

Exploring the Benefits of Wire Deck Railing: A Comprehensive Guide to Safety and Aesthetics