2025 Top Stainless Steel Cable Uses Benefits and Buying Guide

In the evolving landscape of industrial materials, stainless steel cable stands out as a versatile and reliable choice for various applications. According to renowned industry expert John Smith, "Stainless steel cables are not just about strength; they embody resilience and adaptability in a wide range of contexts." This quote underscores the growing recognition of stainless steel cables as essential components across numerous sectors, from construction and marine applications to automotive and aerospace industries.

With their remarkable resistance to corrosion and durability, stainless steel cables offer significant advantages over traditional materials. As we approach 2025, it becomes imperative to explore the diverse uses of stainless steel cables, their unique benefits, and key considerations for purchasing. This guide aims to provide insights into the current trends shaping the industry, helping both enthusiasts and professionals make informed decisions in their designs and projects involving stainless steel cables. The demand for high-quality, reliable cable solutions is only set to increase, making it crucial to understand how to navigate this essential market.

Top Applications of Stainless Steel Cable in Various Industries

Stainless steel cables have become essential across various industries due to their remarkable strength, durability, and resistance to corrosion. In the construction industry, these cables are widely used for suspension bridges and high-rise buildings, where structural integrity is paramount. According to a report by the International Journal of Steel Structures, stainless steel cables can withstand loads 20% higher than their carbon steel counterparts, making them ideal for supporting heavy structures and ensuring safety over time.

In the marine sector, stainless steel cables are favored for mooring lines and rigging systems due to their ability to resist rust and degradation in harsh environments. The Marine Engineering Journal notes that the use of stainless steel in marine applications has increased by approximately 30% over the last five years, reflecting its reliability and the growing demand for sustainable materials in shipbuilding and maintenance.

Tips: When selecting stainless steel cables, consider the specific environment they will be exposed to. For instance, if the cables will be used in a saltwater setting, opting for marine-grade stainless steel can enhance longevity. Additionally, always consult with industry professionals to ensure that you choose cables that meet the precise load requirements and comply with local regulations.

2025 Top Applications of Stainless Steel Cable

This chart illustrates the top applications of stainless steel cables across various industries in 2025, highlighting their usage and benefits.

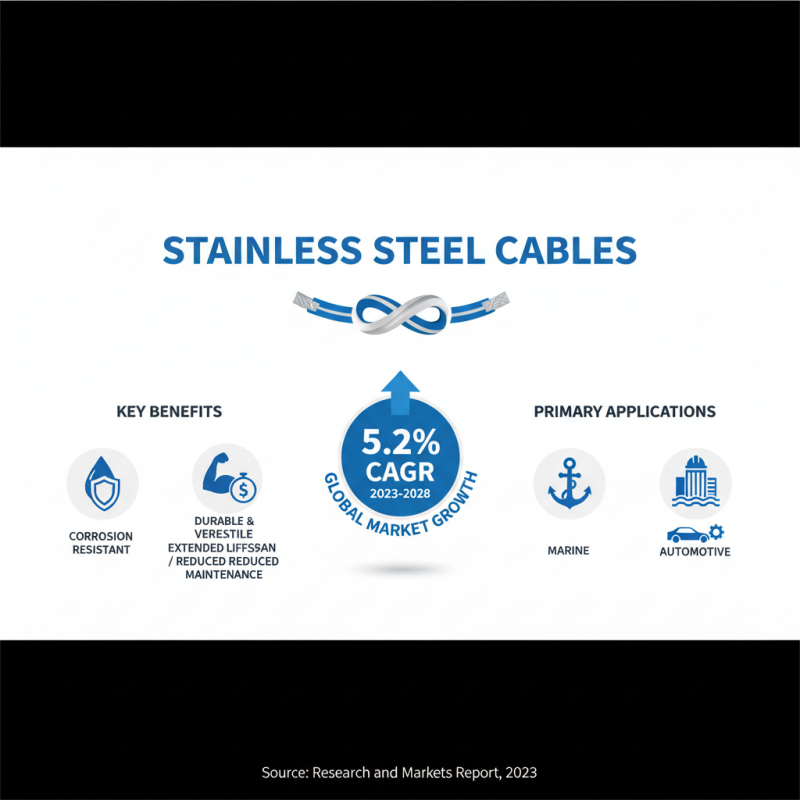

Key Benefits of Using Stainless Steel Cables for Projects

Stainless steel cables have become increasingly popular across various industries due to their remarkable durability and versatility. According to a recent report by Research and Markets, the global market for stainless steel cables is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2028, reflecting their rising demand in construction, marine, and automotive applications. One key benefit of using stainless steel cables is their exceptional resistance to corrosion, making them ideal for outdoor settings or environments exposed to moisture and humidity. This resistance extends the lifespan of the cables, reducing maintenance costs and the need for frequent replacements.

Another significant advantage of stainless steel cables is their high tensile strength, which allows them to withstand substantial loads without stretching or breaking. The American Society for Testing and Materials (ASTM) indicates that stainless steel can have a tensile strength ranging from 70,000 to 250,000 psi, depending on the grade. This makes them particularly suited for applications requiring robust support, such as suspension bridges and architectural projects. Additionally, their lightweight nature, combined with high strength, enables easier handling and installation, further enhancing their attractiveness for contractors and engineers alike.

Factors to Consider When Purchasing Stainless Steel Cables

When purchasing stainless steel cables, several key factors must be taken into consideration to ensure you select the right product for your specific needs. First and foremost, it's essential to assess the types of stainless steel used in the cables. Different grades offer varying levels of corrosion resistance, strength, and flexibility. For instance, Type 304 is commonly used for general purposes, while Type 316 provides enhanced protection against harsh environments, making it ideal for marine applications.

Another crucial aspect is the cable diameter and construction. The thickness of the cable will significantly influence its load-bearing capacity and overall performance. Additionally, the construction style—such as 7x19 or 1x19 configurations—affects the cable's flexibility and ability to handle bending without kinking. It's also vital to evaluate the working load limit, which should not exceed the manufacturer's recommendations to ensure safety and longevity. Understanding these factors will help you make an informed decision, ultimately leading to more efficient and effective use of stainless steel cables in your projects.

Types of Stainless Steel Cables and Their Specifications

Stainless steel cables are versatile and come in various types, each tailored for specific applications and environments. One common type is the 304 stainless steel cable, known for its excellent corrosion resistance and good strength, making it ideal for general indoor and outdoor uses. It is widely utilized in architectural applications, such as railing systems and suspensions. However, for more demanding environments, 316 stainless steel cables, which contain molybdenum, offer superior resistance to saltwater corrosion, making them perfect for marine and coastal applications where exposure to harsh conditions is prevalent.

When selecting a stainless steel cable, it's crucial to consider specifications such as diameter, breaking strength, and construction. Common diameters range from 1/16 inch to 3/8 inch, with larger cables offering increased strength but also increased weight. Additionally, the cable construction—such as 7x19 or 7x7—indicates the number of strands and wires used, influencing flexibility and strength. Understanding these specifications ensures that the chosen stainless steel cable meets the required load-bearing capacity and flexibility, ultimately enhancing performance in its intended application.

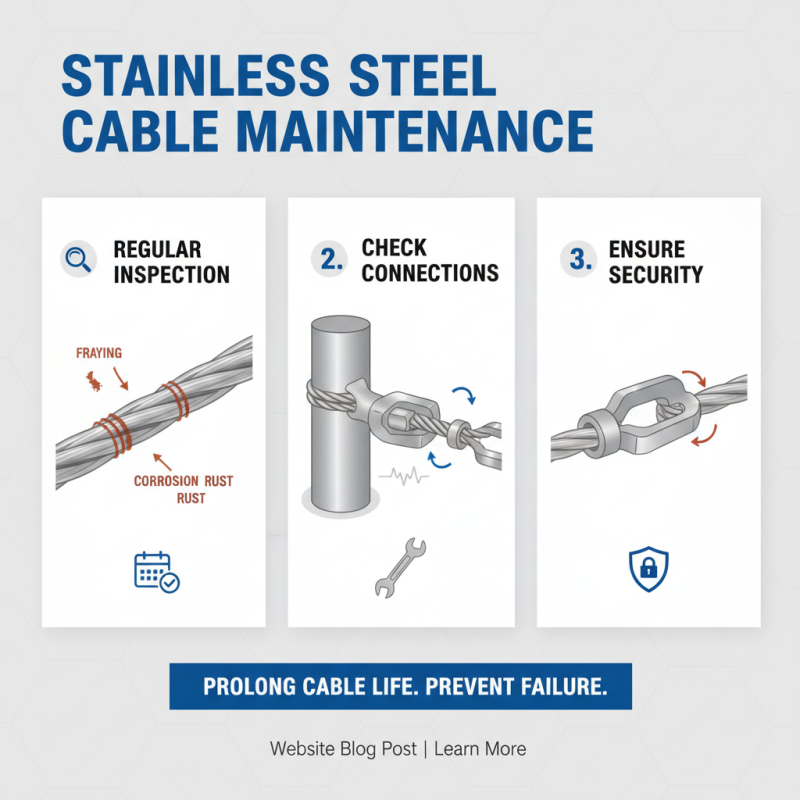

Maintenance Tips for Longevity of Stainless Steel Cables

Maintaining stainless steel cables is essential for ensuring their longevity and optimal performance. One key aspect of maintenance is regular inspection. Look for signs of wear, such as fraying, corrosion, or rust, which can indicate a potential failure. It's important to check the cable’s connections and fittings, ensuring that they are secure and not subject to excessive movement or vibration. Establishing a routine inspection schedule will help catch any issues before they escalate.

Additionally, proper cleaning is vital to prevent the buildup of dirt, grime, and other contaminants. Mild soap and water can be effective for routine cleaning, while more stubborn stains may require specialized cleaners designed for stainless steel. After cleaning, thoroughly rinse and dry the cables to prevent water spots and corrosion. Furthermore, it's advisable to store stainless steel cables in a dry environment when not in use, as moisture can contribute to the deterioration of the material over time. By following these maintenance tips, you can significantly extend the lifespan of your stainless steel cables and ensure they perform efficiently for years to come.

Related Posts

-

Why Stainless Steel Cable Is Your Best Choice for Durability and Strength

-

Exploring Growth Opportunities for Stainless Steel Cable Railing Systems at the 138th Canton Fair 2025

-

Why Metal Cable Railings are the Future of Modern Outdoor Design: A Comprehensive Guide

-

10 Reasons Why Steel Cable Railing is the Best Choice for Modern Decks: Safety, Durability & Style Insights

-

How to Choose the Best Wire Railing for Your Outdoor Spaces: 2023 Expert Guide

-

Exploring the Benefits and Design Options of Modern Cable Railing Systems for Homes