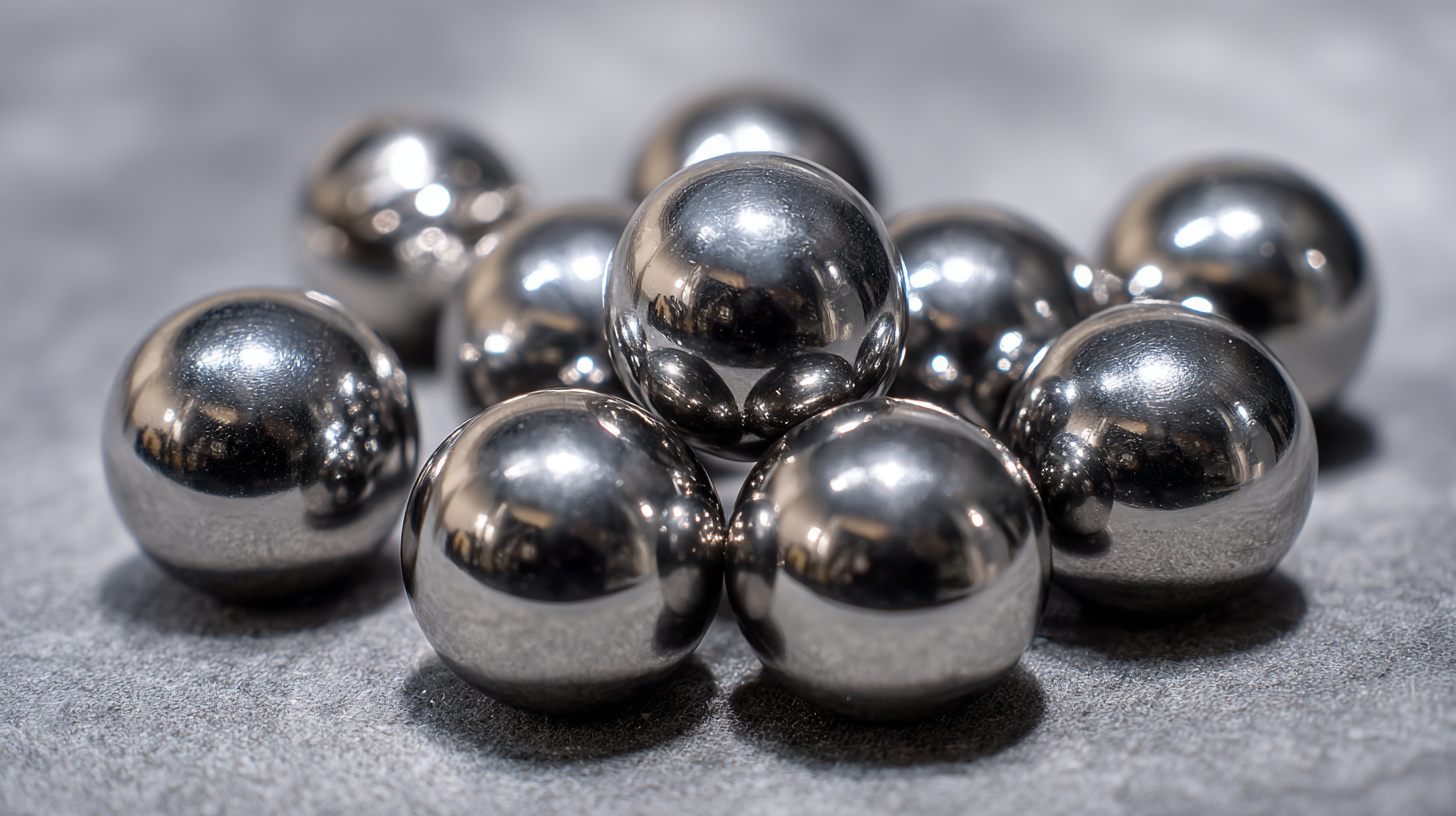

In recent years, the global demand for high-quality stainless steel balls has surged, driven by their extensive applications across various industries, including automotive, aerospace, and machinery. According to a report by MarketsandMarkets, the stainless steel ball market is anticipated to reach a value of USD 6.02 billion by 2026, growing at a CAGR of 5.9% from 2021 to 2026. This growth reflects the increasing reliance on durable and corrosion-resistant components, essential for enhancing product longevity and performance. As leading manufacturers in China respond to this rising trend, global buyers are discovering that these stainless steel balls not only meet rigorous standards but also offer competitive pricing. This ultimate guide will delve into the advantages of sourcing stainless steel balls from top Chinese manufacturers, exploring the quality standards, production processes, and key factors that distinguish them in the global marketplace.

When searching for reliable stainless steel ball manufacturers, global buyers should prioritize a few key characteristics that signal quality and trustworthiness. According to a report by Grand View Research, the global stainless steel ball market is expected to reach $3.14 billion by 2025, driven by increasing demand across industries such as automotive, aerospace, and manufacturing. Thus, identifying the right manufacturer becomes crucial in ensuring that the products meet the stringent standards required in these sectors.

One essential factor is the manufacturer’s adherence to international quality certifications like ISO 9001. A report from Market Research Future indicates that 68% of buyers consider quality certification as a significant criterion when selecting suppliers. Manufacturers with robust quality control processes are more likely to produce stainless steel balls that meet or exceed industry specifications. Additionally, having a wide range of material grades available, such as AISI 440C or AISI 316, allows manufacturers to cater to diverse application needs, further enhancing their reliability in the eyes of global buyers. Attention to detail in surface finish and tolerance specifications can also indicate a manufacturer’s commitment to quality, ensuring superior performance in their products.

When sourcing stainless steel balls, it is essential to evaluate the credentials and certifications of potential suppliers, especially when dealing with manufacturers from overseas. Leading Chinese manufacturers often possess a variety of quality assurance certifications, such as ISO 9001, which indicates adherence to international quality management standards. Additionally, certifications like ASTM and SAE can assure buyers that the products meet specific technical specifications, ensuring reliability and performance.

**Tip 1:** Always request documentation of certifications from your supplier. This not only verifies their claims but also provides peace of mind regarding the quality of the products you are purchasing.

Moreover, it is beneficial to look into the supplier’s history and reputation in the industry. Reviews and ratings from previous buyers can provide valuable insights into the reliability of the manufacturer. Engaging with suppliers who have a strong track record can ensure a smoother transaction and better quality outcomes.

**Tip 2:** Consider conducting a background check or even visiting the manufacturer if possible. This can help you assess their production processes and commitment to quality firsthand, enabling you to make informed purchasing decisions.

This chart displays the evaluation of different quality assurance certifications held by stainless steel ball manufacturers in China, illustrating the importance of supplier credentials in the global market.

When considering a partnership with a stainless steel supplier, it’s essential to ask the right questions to ensure quality and reliability. First, inquire about the manufacturer’s certifications and quality control processes. This is vital since the global stainless steel market is projected to reach $320.37 billion by 2032. Understanding their compliance with international standards can significantly affect the performance and durability of the products you receive.

Another critical question revolves around the supplier's ability to meet your specific requirements. Are they flexible enough to customize their products for your needs? Additionally, it’s important to evaluate their production capacity and lead times. A reliable supplier should provide transparent timelines and demonstrate their commitment to meeting deadlines. Lastly, don’t overlook the importance of after-sales support. A strong partnership is built on effective communication and assistance throughout the entire procurement process, which ultimately fosters a more productive relationship.

When it comes to sourcing stainless steel balls from leading manufacturers in China, making informed decisions requires a careful balance between price and quality. While lower prices can be tempting, they may often reflect compromises in craftsmanship or material integrity. Therefore, it’s essential for global buyers to evaluate potential suppliers holistically.

Tip 3: Assess the manufacturer's reputation by looking at customer reviews and feedback. Understanding the experiences of previous buyers can provide valuable context, enabling you to make a more informed choice that aligns quality with price.

Building long-term relationships with your steel ball supplier is crucial for maintaining consistent quality and supply in the competitive global market. One effective strategy is to prioritize open communication. Regular check-ins to discuss production timelines, quality standards, and any potential challenges can foster trust and transparency. By keeping the lines of communication open, both parties can address issues proactively, ensuring that the partnership remains strong and beneficial.

Another key strategy is to invest time in understanding your supplier’s capabilities and innovations. By visiting the manufacturing facility or participating in workshops, you can gain insight into their processes and quality control measures. This knowledge allows you to better align your expectations with their offerings and enables you to support them in implementing improvements. Furthermore, showing genuine interest in their operations can strengthen the partnership, as suppliers appreciate clients who are invested in their success.