The Science Behind Stainless Mesh and Its Impact on Modern Industries

In modern industries, the utilization of stainless mesh has become increasingly vital, leveraging its unique properties to enhance efficiency and safety across various applications. According to a report by Grand View Research, the global market for stainless steel mesh is projected to reach USD 2.1 billion by 2025, growing at a CAGR of 4.6%. This growth is driven by the material's corrosion resistance, strength, and versatility, making it ideal for diverse fields such as food processing, pharmaceuticals, and construction. Stainless mesh plays a crucial role in filtration, support structures, and reinforcing elements, demonstrating its impact on innovation and productivity. As industries continue to evolve, the adoption of stainless mesh is expected to expand, marking it as a key player in contemporary engineering solutions and contributing to advancements in sustainability and safety.

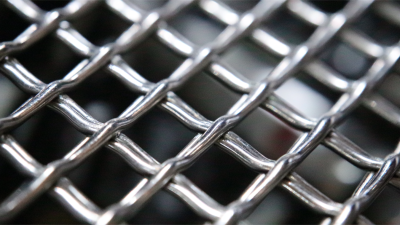

Understanding the Composition and Properties of Stainless Mesh

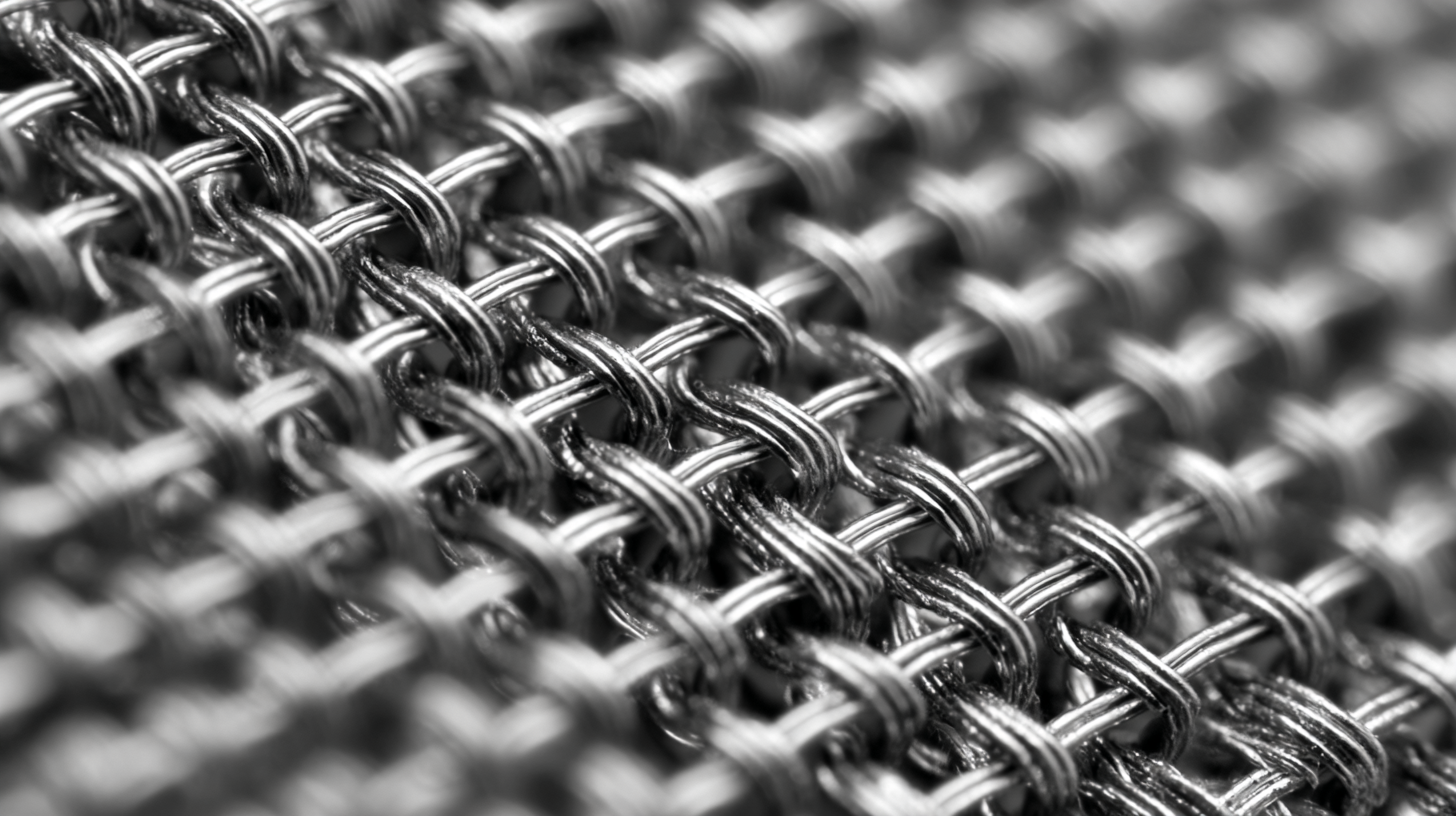

Stainless mesh, an essential material in various modern industries, is primarily composed of stainless steel alloys, which offer exceptional durability and resistance to corrosion. The common types of stainless steel used in mesh production include 304 and 316 grades, each providing distinct advantages depending on the application. The unique properties of stainless mesh, such as its high tensile strength and versatility, make it ideal for filtration, separation, and reinforcement purposes in sectors ranging from construction to food processing.

Tips: When selecting stainless mesh for your project, consider the specific environment it will be exposed to. For instance, 316 stainless steel is often recommended for marine applications due to its superior resistance to saltwater corrosion. Additionally, understanding the mesh's opening size is crucial for applications requiring precise filtration; a finer mesh will be necessary for capturing smaller particles.

Moreover, stainless mesh offers excellent thermal and electrical conductivity, making it a preferred choice in electronic applications and high-temperature environments. Its lightweight yet robust nature allows it to be easily fabricated into complex shapes while maintaining structural integrity. As industries continue to evolve, the role of stainless mesh will undoubtedly expand, making it a material worth investing in for long-term reliability and performance.

The Science Behind Stainless Mesh and Its Impact on Modern Industries - Understanding the Composition and Properties of Stainless Mesh

| Property | Description | Industrial Application |

|---|---|---|

| Corrosion Resistance | Stainless mesh is highly resistant to rust and corrosion due to its chromium content. | Oil and Gas, Chemical Processing |

| Strength-to-Weight Ratio | Lightweight yet strong, stainless mesh offers excellent tensile strength. | Automotive, Aerospace |

| Filtration Efficiency | Effective in filtering liquids and gases, retaining particles of various sizes. | Water Treatment, Food and Beverage |

| Temperature Resistance | Can withstand high temperatures without losing structural integrity. | Manufacturing, Boiler Operations |

| Versatility | Can be engineered for various applications, available in different grades and mesh sizes. | Construction, Electronics |

Exploring the Manufacturing Process: From Raw Materials to Final Product

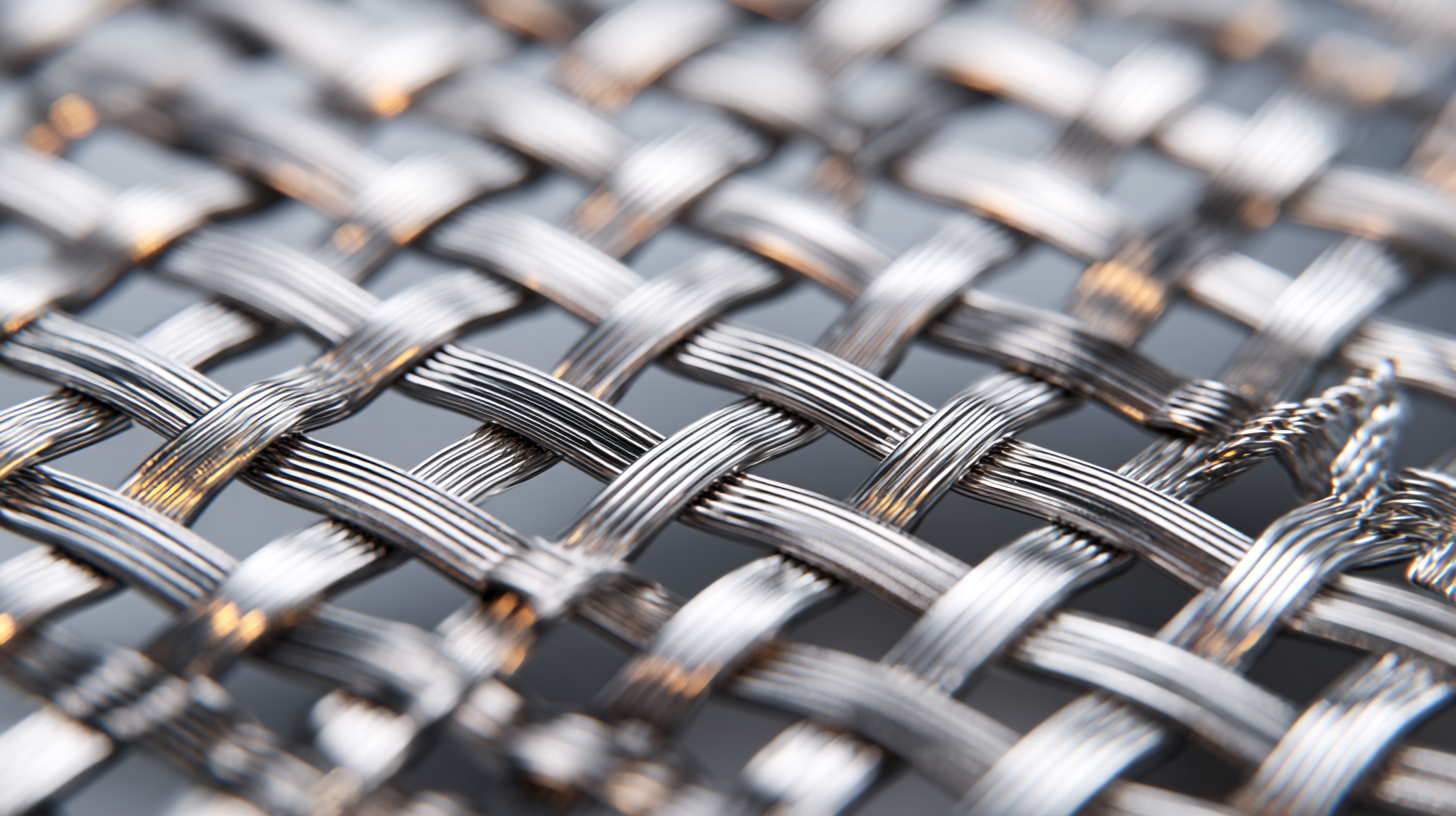

The manufacturing process of stainless mesh begins with the careful selection of raw materials, primarily stainless steel alloys. The most commonly used grades include 304 and 316, chosen for their exceptional corrosion resistance and tensile strength. Once the materials are sourced, they are melted in high-temperature furnaces, ensuring a homogeneous blend. This molten steel is then cast into ingots or slabs, which are subsequently hot-rolled and cold-rolled to achieve the desired thickness and mechanical properties.

The manufacturing process of stainless mesh begins with the careful selection of raw materials, primarily stainless steel alloys. The most commonly used grades include 304 and 316, chosen for their exceptional corrosion resistance and tensile strength. Once the materials are sourced, they are melted in high-temperature furnaces, ensuring a homogeneous blend. This molten steel is then cast into ingots or slabs, which are subsequently hot-rolled and cold-rolled to achieve the desired thickness and mechanical properties.

After rolling, the stainless steel undergoes wire drawing, where the steel is pulled through a series of dies to produce fine wires. These wires are then woven into mesh using various techniques, such as plain weave or twill weave, depending on the specific application requirements. The woven mesh is then subjected to a range of finishing processes, including surface treatments and coatings to enhance durability. This intricate manufacturing process not only ensures that the stainless mesh meets strict quality standards but also positions it as a vital component in diverse industries, from food processing to aerospace, where efficiency and reliability are paramount.

Applications of Stainless Mesh in Various Modern Industries

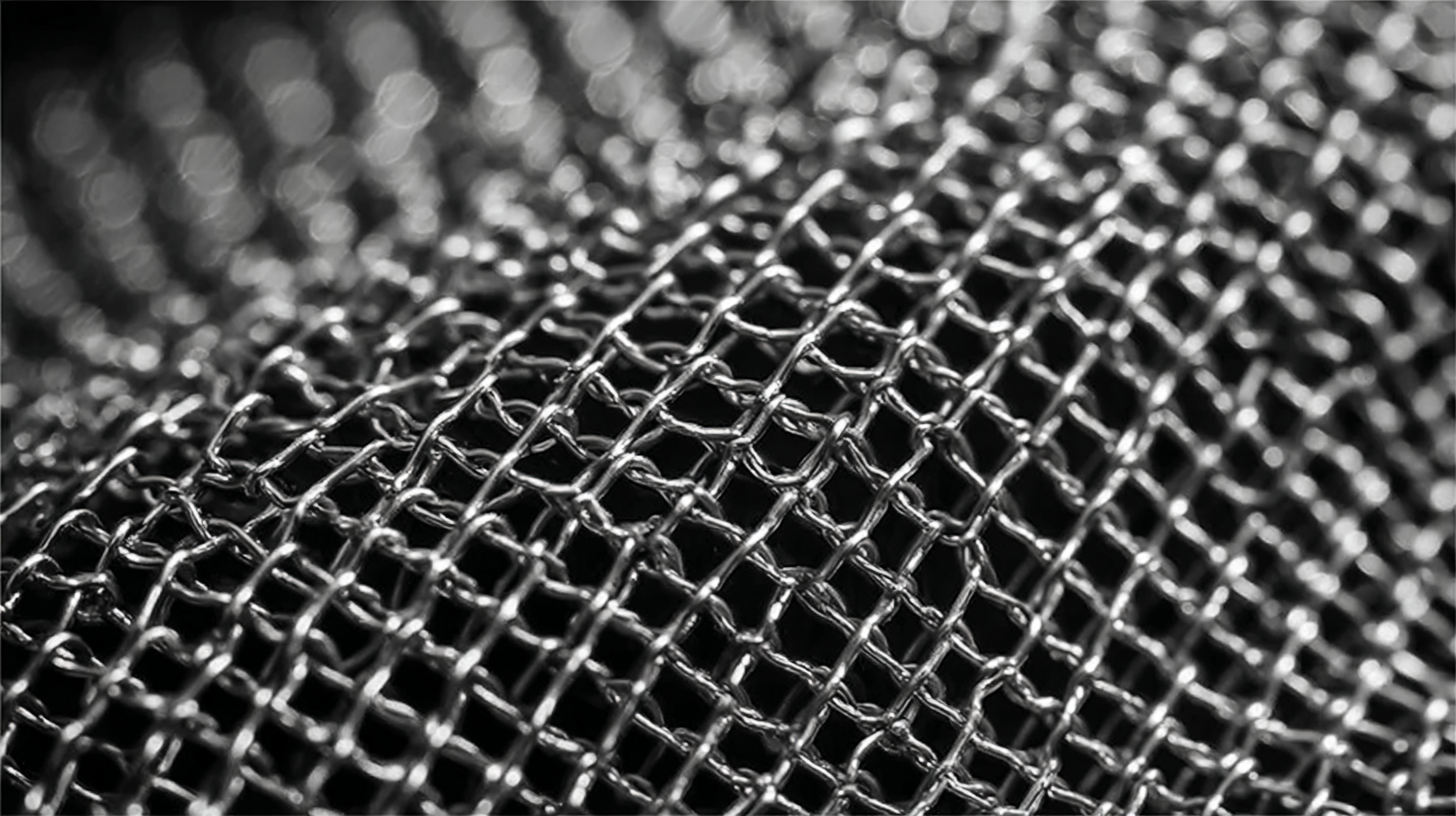

Stainless mesh plays a crucial role in various modern industries due to its unique properties, such as corrosion resistance, durability, and versatility. In the food and beverage sector, stainless mesh is utilized for filtration and separation processes, ensuring that products meet stringent safety and quality standards. Its ability to withstand rigorous cleaning processes without degrading makes it ideal for applications in processing plants, where hygiene is paramount.

In the construction and manufacturing industries, stainless mesh serves multiple functions, including reinforcement in concrete and as protective barriers. Its strength enhances the structural integrity of buildings while allowing for aesthetic designs. Furthermore, in the automotive and aerospace sectors, stainless mesh is employed in components that require lightweight yet strong materials, contributing to improved fuel efficiency and performance. The widespread adoption of stainless mesh across these industries showcases its adaptability and significance in advancing technological innovation.

Evaluating the Benefits of Stainless Mesh for Durability and Versatility

Stainless mesh has gained traction across various industries due to its impressive durability and versatility. According to a report from MarketsandMarkets, the global market for stainless steel mesh is projected to grow significantly, driven by its applications in construction, automotive, and filtration systems. The alloy's resistance to corrosion and high tensile strength make it an ideal choice for demanding environments, enabling manufacturers to enhance the longevity of their products while reducing maintenance costs.

One notable benefit of stainless mesh is its adaptability. The mesh can be fabricated into different shapes and sizes, catering to specific applications such as industrial filtration, architecture, and even medical devices. A study by Research and Markets indicates that the automotive sector's increasing demand for lightweight yet strong materials has led to an uptick in stainless mesh usage, thus promoting fuel efficiency and safety.

Tips:

When selecting stainless mesh for your projects, consider the specific environmental conditions to which it will be exposed. This will ensure maximum performance and longevity. Additionally, always consult industry specifications to choose the appropriate wire diameter and mesh count that aligns with your operational needs.

Future Innovations and Trends in Stainless Mesh Technology

The stainless mesh industry is experiencing rapid advancements driven by innovations in material science and manufacturing techniques. According to a recent report by MarketsandMarkets, the global stainless steel market is projected to reach $139 billion by 2025, with increasing demand for stainless mesh products in various applications, including filtration, construction, and automotive sectors. This growth is fueled by the material's corrosion resistance, strength, and versatility, making it a preferred choice for both industrial and consumer goods.

Future trends indicate a shift towards incorporating advanced technologies such as automation and smart manufacturing processes. For instance, the introduction of 3D printing techniques for stainless mesh production is set to revolutionize the industry by enabling the creation of complex geometries that were previously impossible or cost-prohibitive. Furthermore, sustainability is becoming paramount; manufacturers are focusing on eco-friendly practices and materials, aligning with the global movement towards greener production methods. As industries seek to enhance efficiency and reduce their carbon footprint, the integration of stainless mesh technology is expected to play a crucial role in achieving these objectives.

The Science Behind Stainless Mesh Usage in Various Industries

Related Posts

-

Exploring Cable Railing Innovations at the 138th Canton Fair 2025 in China

-

Exploring Cable Fence Innovations at the 138th China Import and Export Fair 2025

-

Exploring Stainless Steel Mesh Innovations at the 138th Canton Fair 2025: Industry Trends and Insights

-

Exploring Growth Opportunities for Stainless Steel Cable Railing Systems at the 138th Canton Fair 2025

-

Revolutionizing Safety: The Impact of Cable Handrail Systems on Modern Architecture

-

The Ultimate Guide to Choosing the Right Cable Stair Railing for Your Home Decor