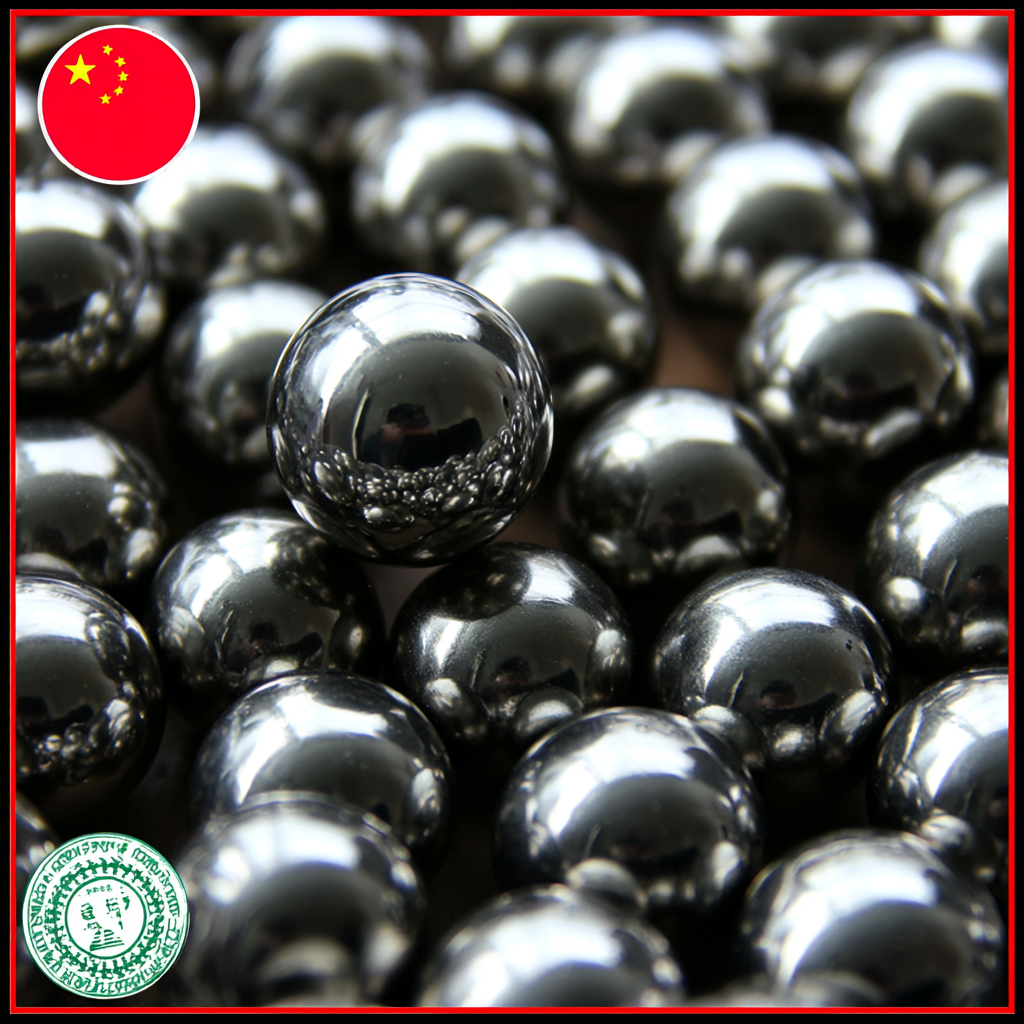

The global bearing steel ball market has witnessed remarkable growth, driven by the increasing demand from sectors such as automotive, aerospace, and industrial machinery. According to a recent report by Market Research Future, the bearing steel ball segment is expected to reach a valuation of over $5 billion by 2025, growing at a CAGR of approximately 6.2%. This growth is largely attributed to advancements in manufacturing techniques and the rising emphasis on the quality of raw materials used. China stands out as a pivotal player in this industry, renowned for its exemplary production capabilities, which have positioned it as a leading exporter of high-quality bearing steel balls. The combination of technological innovation, stringent quality control measures, and cost-effective production practices has enabled China to set a benchmark in the global market, ensuring that its bearing steel balls meet the rigorous demands of international clients.

As we look towards 2025, the production of bearing steel balls is set to undergo significant transformation, driven by technological advancements and a deeper understanding of material science.

The implementation of automation and smart manufacturing processes is becoming increasingly prevalent, enabling manufacturers to produce high-quality steel balls with greater precision and efficiency. Innovations such as artificial intelligence and machine learning are optimizing production schedules and reducing waste, ensuring that the end products meet stringent quality standards.

The implementation of automation and smart manufacturing processes is becoming increasingly prevalent, enabling manufacturers to produce high-quality steel balls with greater precision and efficiency. Innovations such as artificial intelligence and machine learning are optimizing production schedules and reducing waste, ensuring that the end products meet stringent quality standards.

Furthermore, sustainability is emerging as a critical focus in the bearing steel ball industry. Companies are exploring eco-friendly materials and manufacturing processes to minimize their environmental impact.

Recycling scrap steel and utilizing alternative energy sources are just a few ways producers are aligning with global sustainability goals. With consumer demand for greener products on the rise, businesses that prioritize sustainable practices will likely gain a competitive edge in the market.

These trends not only indicate a shift towards more responsible manufacturing but also signal a bright future for the bearing steel ball sector as it embraces innovation and environmental stewardship.

In the realm of precision engineering, bearing steel balls are pivotal components that play a critical role in various industries, from automotive to aerospace. The latest innovations in bearing steel manufacturing signal a transformative era, promising enhancements in durability, performance, and cost-efficiency. Advanced metallurgy techniques are paving the way for the production of steel balls that exhibit superior wear resistance and reduced friction, essential factors for prolonging the lifespan of machinery.

Furthermore, the integration of smart manufacturing technologies, such as real-time monitoring and AI-driven quality control, has revolutionized production processes. These innovations ensure that every steel ball meets stringent quality standards, significantly minimizing defects. As Chinese manufacturers embrace these technological advancements, they are not only improving product quality but also setting new benchmarks for sustainable production practices. This evolution in bearing steel ball manufacturing is poised to enhance global competitiveness and meet the increasing demand for high-performance components worldwide.

In recent years, the bearing steel industry in China has made significant strides towards sustainability, reflecting the country’s commitment to high-quality development. The focus on producing exemplary bearing steel balls has not only enhanced product quality but also promoted environmental responsibility. Industry leaders have emphasized the importance of integrating advanced technology and sustainability practices in their production processes to meet both domestic and global demands.

A key aspect of this transformation is the adoption of big data analytics in quality management. Companies have started utilizing predictive modeling to forecast production quality, enabling dynamic composition control. Such innovative approaches have exhibited commendable results, with reports indicating that utilizing data-driven strategies can increase efficiency by up to 30% while reducing material waste. Furthermore, these practices contribute to lower carbon footprints, aligning with global sustainability goals.

As reflected in recent industry assessments, China’s bearing steel production capabilities showcase both quality and innovation. The pursuit of excellence in this sector demonstrates how traditional manufacturing can evolve through modern practices, enhancing sustainability without compromising on performance. This combination of quality management and environmental stewardship positions China's bearing steel industry as a leader on the world stage.

This chart illustrates the production volume of bearing steel balls from 2019 to 2023, indicating an upward trend in sustainability practices within China's bearing steel industry.

When selecting the best quality bearing steel balls for your applications, it's crucial to consider several key factors to ensure optimal performance and longevity. First, look for stainless steel or high-carbon steel options, as these materials provide excellent resistance to wear and corrosion. The hardness of the steel is another essential aspect; typically, hardness levels around 60-66 HRC are ideal for maintaining durability under stress.

Tip: Always check the manufacturer’s specifications and certifications to confirm the steel's quality and compliance with industry standards. Additionally, consider the size and tolerance of the bearing balls, as precise dimensions are vital for achieving smooth operation in machinery.

Moreover, don’t overlook the importance of lubrication and operating conditions. Ensure that the steel balls are compatible with the lubricant being used, as this will significantly influence their performance.

Tip: Performing regular maintenance checks and understanding the environment where the bearings will operate can prevent premature wear and enhance efficiency. By focusing on these factors, you can make an informed decision when choosing bearing steel balls that meet your specific requirements.

The bearing steel balls industry is experiencing a significant transformation, poised for remarkable growth in global trade. According to a recent market research report, the global bearing market is expected to reach USD 73.39 billion by 2028, growing at a CAGR of 7.2%. This burgeoning demand is driven by advancements in technology and the increasing use of bearing steel balls in automotive, aerospace, and machinery applications. As manufacturers from China continue to excel in production quality and efficiency, they are set to capture a larger share of the international market.

Tips for industry players include focusing on innovation and quality control. Investing in automated production techniques can enhance precision and reduce costs. Additionally, understanding customer needs and adapting to regional preferences can provide competitive advantages in varied markets. The implementation of stringent quality standards, coupled with sustainable practices, will ensure long-term success in the global landscape.

With emerging markets such as India and Southeast Asia ramping up their industrial capabilities, opportunities abound for bearing steel balls. Companies that strategically position themselves to tap into these markets stand to benefit substantially. Engaging in partnerships and alliances can facilitate smoother entries into these regions, ultimately driving growth and profitability in the evolving global trade environment.

| Region | Market Size (USD Billion) | Growth Rate (%) | Main Applications | Key Trends |

|---|---|---|---|---|

| North America | 2.5 | 4.5 | Automotive, Aerospace | Increasing demand for precision engineering |

| Europe | 3.0 | 3.8 | Industrial Machinery, Electrical | Innovation in materials and manufacturing processes |

| Asia-Pacific | 5.0 | 6.5 | Consumer Electronics, Heavy Equipment | Rapid industrialization and urbanization |

| Latin America | 1.2 | 3.0 | Mining, Agriculture | Focus on sustainability and environmental impact |

| Middle East & Africa | 0.8 | 2.9 | Oil & Gas, Construction | Growing investment in infrastructure |