Why Choose Stainless Mesh for Your Next Project? Key Benefits Explained

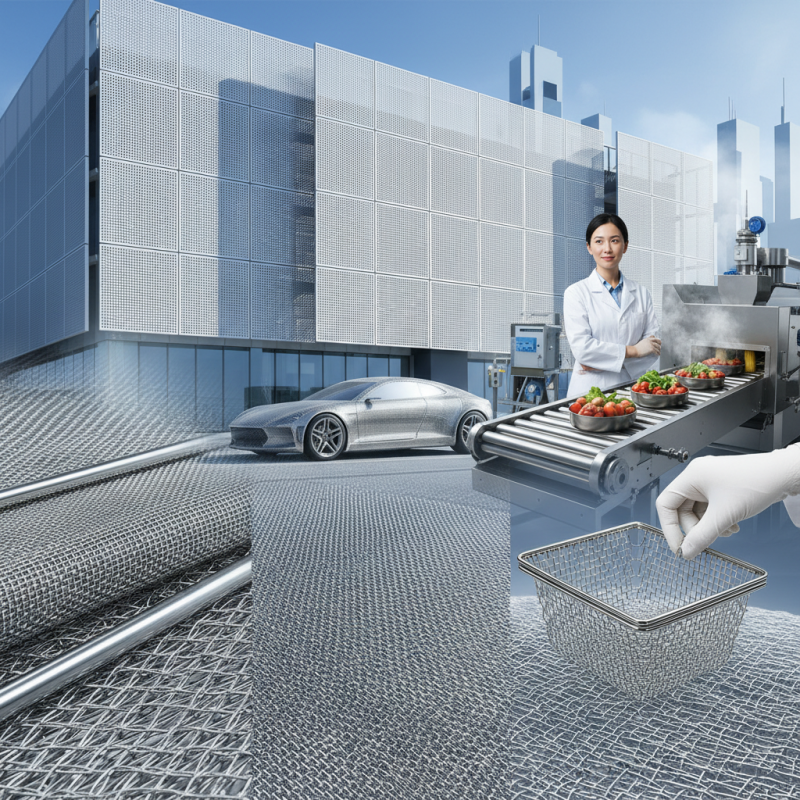

Stainless mesh has become an essential material in various industries due to its remarkable durability, corrosion resistance, and versatility. According to a recent report by Market Research Future, the global market for stainless steel mesh is expected to reach USD 3.5 billion by 2025, driven by the growing demand in sectors such as construction, automotive, and food processing. This highlights a significant trend that underscores the material's importance in modern project development.

Industry expert Dr. Emily Chen, a leading metallurgist with over 15 years of experience in stainless products, emphasizes the advantages of stainless mesh, stating, "The unique properties of stainless mesh not only enhance the performance of industrial applications but also contribute to sustainability efforts by reducing the need for frequent replacements." With its ability to withstand harsh environments and maintain structural integrity over time, stainless mesh is rapidly becoming the go-to choice for engineers and architects seeking reliable materials for their next projects.

Incorporating stainless mesh into your designs not only assures longevity but also elevates aesthetic appeal, making it an optimal solution for both functional and decorative uses. As industries continue to innovate, the significance of stainless mesh is poised to grow, marking it as a pivotal element in successful project execution.

Understanding Stainless Mesh: What It Is and How It Works

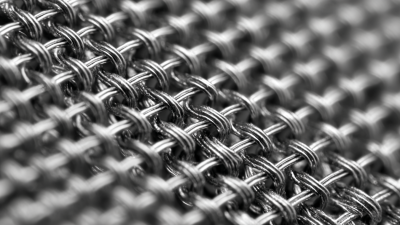

Stainless mesh, a versatile and durable material, has garnered attention in various industries for its unique properties and applications. Comprised primarily of stainless steel woven into a fine mesh structure, it exhibits remarkable resistance to corrosion, making it ideal for environments that demand both strength and longevity. In fact, according to industry reports, stainless steel grades 304 and 316 are widely used in mesh applications due to their superior corrosion resistance, which is crucial in sectors such as food processing and pharmaceuticals where hygiene is paramount.

The functionality of stainless mesh extends beyond mere durability. Its design allows for optimal filtration and separation processes in various applications, from sieving materials in construction to filtering liquids in chemical processing. A 2021 market analysis highlighted that the global demand for specialized stainless mesh solutions is projected to increase by over 5% annually, driven by innovations in manufacturing and a growing emphasis on sustainable practices. Moreover, the mesh's ability to be customized in terms of wire diameter and aperture size caters to specific project needs, ensuring efficiency and cost-effectiveness. With its exceptional mechanical properties and adaptability, stainless mesh stands out as a prime choice for professionals seeking reliable solutions for their next project.

Key Benefits of Using Stainless Mesh in Various Applications

Stainless mesh is a versatile material that finds extensive applications across various industries due to its unique properties. One of the key benefits is its exceptional corrosion resistance, which makes it ideal for use in environments exposed to moisture, chemicals, or harsh weather conditions. This durability ensures that stainless mesh maintains its integrity over time, providing a long-lasting solution for filtration, separation, and support systems. Whether in food processing, pharmaceuticals, or outdoor architectural elements, the resilience of stainless mesh enhances the overall lifespan of products.

Another significant advantage of stainless mesh is its ease of maintenance. Unlike other materials that may require frequent replacement or intensive upkeep, stainless mesh can be easily cleaned and sanitized, making it particularly useful in healthcare and food service applications. Additionally, its lightweight yet strong nature adds to its functionality, allowing for effortless installation and adaptation in various projects. As industries increasingly focus on sustainability, choosing stainless mesh can contribute to reducing waste and promoting environmentally friendly practices, thanks to its recyclability and long service life.

Why Choose Stainless Mesh for Your Next Project? Key Benefits Explained

| Application | Key Benefit | Why Stainless Mesh? |

|---|---|---|

| Filtration | Corrosion Resistance | Withstands harsh chemicals and environments. |

| Construction | Strength and Durability | Offers high tensile strength and suitable for heavy-duty use. |

| Food Processing | Hygienic Properties | Non-reactive surface ensures food safety. |

| Architecture | Aesthetic Appeal | Modern, sleek look enhances visual designs. |

| Agriculture | Versatility | Ideal for various applications like fencing and drainage. |

Comparative Analysis: Stainless Mesh vs. Other Materials

When considering materials for projects, stainless mesh offers unique advantages over traditional options such as plastic and aluminum. One primary benefit of stainless mesh is its superior durability. Unlike plastics, which can warp or degrade over time due to exposure to UV rays and weather conditions, stainless mesh maintains its structural integrity, making it ideal for both indoor and outdoor applications. Additionally, it is resistant to rust and corrosion, unlike aluminum, which can pit and oxidize in certain environments. This advantage can significantly reduce maintenance costs over the lifespan of a project.

In terms of usability, stainless mesh also excels in filtration and airflow applications. Its fine weave enables efficient separation and filtering without compromising strength. Compared to fibrous materials or less rigid alternatives, stainless mesh provides reliable performance when needed to handle high flow rates or more abrasive substances. Furthermore, its aesthetic appeal adds to its desirability; with a sleek, modern look, it can enhance the overall design of various projects, whether in architectural settings or product enclosures. This combination of strength, durability, and aesthetic versatility makes stainless mesh an outstanding choice for a wide range of applications.

Choosing the Right Type of Stainless Mesh for Your Project

When it comes to selecting the right type of stainless mesh for your project, understanding the specific requirements and benefits is essential. Stainless steel mesh is available in a variety of grades, each tailored for different applications. For instance, type 304 stainless steel is commonly used for its excellent corrosion resistance in a wide range of environments, while type 316 offers superior protection against corrosive elements, such as saltwater, making it ideal for marine applications. According to a report by industry experts, the global market for stainless steel wire mesh is projected to grow by 5% annually, highlighting the increasing demand for specialized mesh solutions in construction, filtration, and architectural design.

Additionally, the mesh's structural properties play a critical role in determining its suitability for your project. The open area, wire diameter, and overall mesh size should align with the intended use. For instance, a mesh with a smaller aperture and thicker wire may be essential for security applications, while a finer mesh is more appropriate for filtration processes. The American Society for Testing and Materials (ASTM) outlines specific standards for wire mesh, ensuring that the materials can withstand environmental stresses. Utilizing accurate specifications not only enhances performance but also increases longevity, with quality stainless mesh lasting decades without requiring replacement, a significant advantage in both residential and industrial settings.

Advantages of Using Stainless Steel Mesh

Maintenance Tips for Durable Stainless Steel Mesh Solutions

Stainless steel mesh is a popular choice for various applications due to its durability and strength. To maintain its effectiveness and ensure a long lifespan, proper care and maintenance are crucial. Regular cleaning is essential to prevent corrosion and buildup of debris. A simple wash with mild soap and warm water followed by thorough rinsing can keep the mesh looking pristine.

For heavy-duty applications, consider using a soft brush to reach between the mesh strands without damaging them.

In addition to regular cleaning, inspecting the mesh for any signs of wear or damage is important. Look for rust spots or breaks in the mesh, which can compromise its integrity. Addressing any issues promptly can prevent larger problems from arising.

If you live in an area with high humidity or salt exposure, consider applying a corrosion-resistant treatment to enhance the mesh's longevity. These small maintenance steps can significantly extend the life of your stainless steel mesh solutions, ensuring their functionality and aesthetic appeal for years to come.

Related Posts

-

The Science Behind Stainless Mesh and Its Impact on Modern Industries

-

Exploring Growth Opportunities for Stainless Steel Cable Railing Systems at the 138th Canton Fair 2025

-

The Ultimate Guide to Installing Steel Cable Railing for Your Home Design

-

How to Choose the Best Wire Railing for Your Outdoor Spaces: 2023 Expert Guide

-

Top 10 Benefits of SS Cable Railing for Modern Home Designs

-

Top Cable Railing Trends for 2025 You Need to Know