How to Choose the Right Steel Cable for Your Project Needs

Choosing the right steel cable for your project is a critical decision that can significantly impact both safety and efficiency. According to John Smith, a noted expert in the steel cable industry, "Selecting the right steel cable involves understanding both the technical specifications and the specific demands of your project." This highlights the importance of thorough research and consideration when deciding on cable types, sizes, and materials.

When evaluating steel cables, one must consider various factors such as load capacity, corrosion resistance, and flexibility. Each project comes with its own set of requirements, making it essential to match these needs with the appropriate cable characteristics. Whether you are working on construction, marine applications, or even automotive uses, the right steel cable can enhance performance and reliability. Therefore, understanding the nuances of steel cable specifications is key for anyone looking to ensure the success of their projects.

Understanding Different Types of Steel Cables and Their Applications

Steel cables come in various types, each designed for specific applications and purposes. Understanding these differences is crucial for selecting the right cable for your project. One common type is the multi-strand wire rope, which consists of several small wires twisted together to form a strong and flexible cable. This type is widely used in heavy lifting and construction due to its superior tensile strength and durability, making it ideal for cranes, elevators, and rigging systems.

Another type is the stainless steel cable, known for its resistance to corrosion and rust. This makes it particularly suitable for outdoor or marine applications where exposure to the elements is a concern. Stainless steel cables are often used in architectural projects such as cable railings or suspension bridges, where both aesthetics and safety are paramount. The choice between these types should consider factors such as load requirements, environmental conditions, and intended use, ensuring optimal performance and longevity for your project.

Key Factors to Consider in Choosing Steel Cable Strength Ratings

When selecting the right steel cable for your project, one of the most significant factors to consider is the strength rating. Steel cables come in various tensile strengths, which indicate how much weight the cable can safely lift or support. Understanding these ratings is crucial, especially when the safety of a load depends on it. For instance, if you are lifting heavy machinery, a cable with a higher tensile strength will be necessary to ensure safety and prevent accidents.

Tips: Always check the manufacturer's specifications for the cable's strength rating before making a purchase. Consider the maximum load you will be handling and choose a cable that can exceed this weight to provide an adequate safety margin. Additionally, factor in environmental conditions that might affect cable strength, such as temperature fluctuations or exposure to chemicals.

Another important aspect to consider is the construction of the steel cable. Different types of cable construction, such as wire rope or strand cable, may offer varying levels of flexibility and durability, which can impact their performance in different applications. Evaluating the specific requirements of your project—such as the need for flexibility, abrasion resistance, or corrosion protection—will help you make an informed choice for the best steel cable to meet your needs.

Tips: If you're unsure which type of construction to choose, consult with professionals or conduct research on the specific applications and environments where the cable will be used. This can save time and ensure that you select a cable that meets your project's demands effectively.

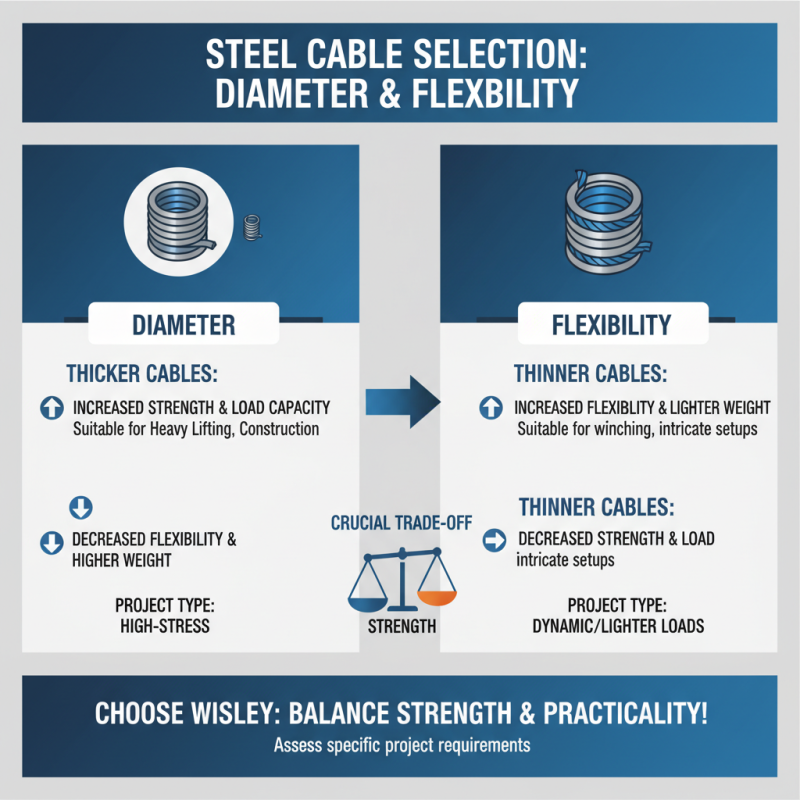

Evaluating Cable Diameter and Flexibility for Project Requirements

When choosing the right steel cable for any project, understanding the cable's diameter and flexibility is crucial. The diameter of the cable significantly influences its strength and load capacity. Thicker cables can typically bear heavier loads, making them suitable for high-stress applications such as construction or heavy lifting. However, a larger diameter also means increased weight and decreased flexibility, which might not be ideal for all projects. It is vital to assess the specific requirements of your project to determine the appropriate diameter that balances strength and practicality.

Flexibility is another key factor in cable selection. A more flexible steel cable allows for easier handling and installation in tight spaces or around sharp corners. This characteristic is particularly important for projects that require dynamic movement or frequently changing positions, such as in rigging or lifting operations. However, increased flexibility often comes at the cost of tensile strength, so it is essential to evaluate the environmental conditions and operational demands of the project. By carefully considering both the diameter and flexibility of the steel cable, you can ensure optimal performance and safety for your project needs.

Assessing Environmental Conditions Impacting Steel Cable Performance

When selecting the appropriate steel cable for a project, it is crucial to assess the environmental conditions that may impact its performance. Factors such as temperature fluctuations, humidity levels, and exposure to corrosive elements can significantly affect the integrity and durability of steel cables. For instance, environments with high moisture content might lead to accelerated rusting if the steel is not appropriately treated or coated. Therefore, understanding the specific environmental circumstances where the cable will be used is essential in making an informed choice.

In addition to moisture and temperature, exposure to chemicals or UV radiation can also play a vital role in the performance of steel cables. In industrial settings, cables may come into contact with oils, lubricants, or various solvents, which can degrade the material over time. Furthermore, in outdoor applications, long-term exposure to sunlight can result in deterioration of protective coatings, leading to increased vulnerability to wear and tear. Assessing these environmental challenges allows for the selection of steel cables that are specifically engineered to withstand the expected conditions, thus ensuring reliability and longevity in any project.

Cost-Effectiveness: Budgeting for Quality Steel Cable Solutions

When budgeting for steel cable solutions, it’s crucial to strike a balance between cost-effectiveness and quality. While it might be tempting to opt for the cheapest option available, investing in high-quality steel cables can save money in the long run by reducing risks associated with failures and maintenance costs. Consider the specific requirements of your project and choose cables that meet industry standards to ensure durability and performance.

Tips for budgeting effectively include researching the different types of steel cables available and understanding their respective benefits. Determine the necessary specifications for your project, such as load capacity and environmental resistance, and compare prices from multiple suppliers. Additionally, don't hesitate to ask for bulk pricing or discounts, as suppliers often offer better deals for larger orders.

Another tip is to factor in the total cost of ownership. This means considering not just the purchase price but also installation and maintenance costs over time. A slightly higher initial investment in a more durable cable can lead to less frequent replacements and lower overall expenses. By prioritizing quality while being mindful of your budget, you can make informed decisions that ensure your project’s success.

Related Posts

-

Exploring the Versatility of Wire Rope: Applications, Benefits, and Care Tips

-

Why Cable Handrails Are the Future of Modern Stair Design: Safety Meets Aesthetics

-

Top Uses and Benefits of Stainless Cable in Various Industries

-

How to Install Cable Railing for Your Deck or Balcony Like a Pro

-

Transforming Spaces: The Ultimate Guide to Cable Handrail System Designs and Installations

-

Exploring Cable Fence Innovations at the 138th China Import and Export Fair 2025