Top 10 Tips for Choosing the Right Stainless Steel Wire Rope for Your Projects

When it comes to selecting the ideal stainless steel wire rope for your projects, making informed decisions is crucial. Industry expert David Thompson, a renowned specialist in materials engineering, once stated, "Choosing the right stainless steel wire rope can significantly enhance the safety and performance of your applications." This insight underscores the importance of understanding the specifications, applications, and characteristics of stainless steel wire ropes.

In various industries, from construction to marine applications, the performance of stainless steel wire rope is paramount. With numerous options available, it is vital to consider factors such as tensile strength, corrosion resistance, and diameter. As projects vary greatly in scope and requirements, staying informed about the latest developments in stainless steel wire rope technology can provide a competitive edge.

This guide will delve into the top 10 tips for choosing the right stainless steel wire rope, ensuring that you are equipped with the knowledge needed to make the best selections for your unique project needs. By following these guidelines, you can maximize the efficiency and durability of your applications, ultimately leading to successful outcomes.

Understanding the Basics of Stainless Steel Wire Rope

Stainless steel wire rope is a critical component in various industrial applications, known for its strength, durability, and resistance to corrosion. Understanding the basics of stainless steel wire rope begins with knowing the different grades and constructions available in the market. The most common grades used include AISI 304 and AISI 316, each offering unique benefits. AISI 304 is suitable for moderate corrosion resistance, while AISI 316 is often preferred for marine or high-chlorine environments due to its enhanced resistance to pitting. According to the International Wire & Rope Products Association, over 70% of stainless steel wire rope applications utilize these grades, emphasizing their reliability in demanding conditions.

When choosing the right stainless steel wire rope, it's important to consider the construction and diameter that best suits the intended use. Common constructions include 7x19 and 6x19, with the former providing increased flexibility while the latter offers more strength. A report from ResearchAndMarkets analysis indicates that the global stainless steel wire rope market is expected to grow at a CAGR of approximately 5.2% from 2021 to 2026, driven by rising demands in the construction, marine, and elevator industries. These constructions influence not only the wire rope's strength and flexibility but also its overall lifespan and maintenance needs, making it essential for project managers to assess their specific requirements before making a selection.

Identifying the Right Diameter and Strength for Your Needs

When selecting the right stainless steel wire rope for your projects, understanding the diameter and strength is crucial for ensuring safety and functionality. The diameter of the wire rope directly affects its load capacity and flexibility. A thicker rope can handle more weight but may be less flexible, which could limit its usability in tight spaces or intricate applications. Conversely, a thinner wire rope may be more maneuverable but will have a lower load-bearing capacity. Therefore, carefully evaluate the specific requirements of your project to find a balance between diameter, strength, and flexibility.

Additionally, the strength of stainless steel wire rope is determined by its construction type and material grade. Different configurations, such as 7x19 or wire strand core, provide varying strength levels suited to distinct applications. For example, if your project involves lifting heavy loads or enduring harsh environmental conditions, opting for a wire rope with higher tensile strength is essential. It’s also important to consider factors like fatigue resistance and corrosion resistance, especially in outdoor or marine applications. Always assess both the anticipated load and any additional stress factors to ensure the chosen wire rope matches your project's demands, offering both safety and reliability.

Evaluating Corrosion Resistance and Environmental Factors

When selecting the right stainless steel wire rope for your projects, evaluating corrosion resistance and environmental factors is crucial. Corrosion can significantly reduce the lifespan and performance of wire ropes, particularly in marine or industrial environments. A study from the International Journal of Corrosion found that stainless steel compositions, particularly those with higher nickel and molybdenum content, can provide superior resistance against pitting and crevice corrosion. For instance, ASTM A313 type 316 stainless steel is often recommended for environments exposed to chlorides, thanks to its enhanced corrosion resistance compared to other types.

Environmental factors also play a significant role in determining the appropriate type of stainless steel wire rope. According to a report from the Metal Construction Association, factors such as humidity, temperature fluctuations, and exposure to chemicals should be taken into account, as they can accelerate the corrosion process. For example, environments with high humidity or frequent temperature changes can lead to increased surface oxidation, making it essential to choose a wire rope that not only has high corrosion resistance but also meets the specific environmental conditions of the project. Proper assessment and selection based on these factors ultimately ensure durability and reliability in demanding applications.

Top 10 Tips for Choosing the Right Stainless Steel Wire Rope for Your Projects

| Tip Number | Tip | Corrosion Resistance | Environmental Factors |

|---|---|---|---|

| 1 | Know the type of stainless steel | Select grades like 304 or 316 for better corrosion resistance | Consider exposure to marine or industrial environments |

| 2 | Assess the diameter required | Thicker wires can provide better resistance | Check load conditions in harsh climates |

| 3 | Inspect wire rope construction | Steel type affects durability against corrosion | Consider locations where moisture accumulates |

| 4 | Evaluate breaking strength | Higher strength can relate to better corrosion treatment | Assess stress factors in the environment |

| 5 | Consider any coatings or treatments | Coatings can improve lifespan in corrosive environments | Analyze exposure to chemicals and weather |

| 6 | Check for certification standards | Compliance can indicate decent corrosion resistance | Ensure standards match project requirements |

| 7 | Assess the tensile strength needed | Choose materials that withstand high tensile conditions | Consider the mechanical demands on the rope |

| 8 | Evaluate cost versus lifespan | Investing more may result in better corrosion resistance | Analyze long-term environmental exposure |

| 9 | Research manufacturer reliability | Reputable brands often have better quality control | Assess how thoroughly the manufacturer tests products |

| 10 | Consider local regulations and codes | Ensure compliance with local corrosion specifications | Verify local environmental factors in regulations |

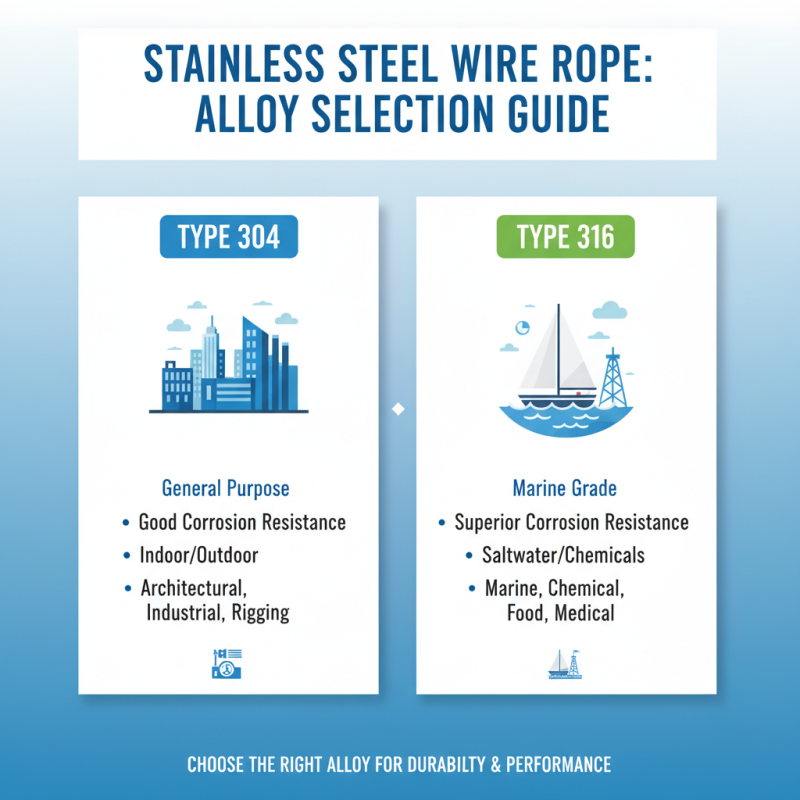

Comparing Different Types of Stainless Steel Alloys

When selecting stainless steel wire rope for various projects, understanding the different types of stainless steel alloys is crucial. The most common alloys used in wire rope manufacturing are 304 and 316 stainless steels, each possessing unique properties that make them suitable for specific applications. Type 304 stainless steel is known for its excellent corrosion resistance in most environments and is often used in general-purpose applications. However, it may not hold up as well in marine or highly corrosive situations.

On the other hand, 316 stainless steel offers superior corrosion resistance, particularly against saltwater and harsh chemicals, making it the preferred choice for marine applications and industrial settings that expose the wire rope to caustic substances. The addition of molybdenum in 316 alloy enhances its durability and performance in challenging environments. When choosing the right stainless steel wire rope, it's essential to consider not only the environmental conditions it will face but also the mechanical strength and flexibility required for your specific project. Understanding these differences enables you to make an informed decision that best suits the demands of your application.

Assessing Cost vs. Performance for Budget-Friendly Choices

When selecting stainless steel wire rope for your projects, balancing cost and performance is crucial to ensure that you meet both your budgetary needs and safety requirements. According to industry reports, such as those from the American Society for Testing and Materials (ASTM), the choice of wire rope can directly impact the efficiency and longevity of your project. High-quality stainless steel wire ropes offer superior resistance to corrosion and wear, which can lead to reduced maintenance costs over time. This key aspect often justifies a higher initial investment.

One important tip to consider is to assess the specific demands of your project. For instance, if your application requires high tensile strength, opting for a wire rope that meets or exceeds ASTM standards is advisable. Additionally, take into account the environment in which the rope will be used. If exposure to harsh weather or corrosive substances is expected, investing in higher-grade stainless steel can save costs on replacements and downtime.

Another useful tip is to compare different suppliers and the specifications of their products. While a lower price may be enticing, it’s essential to evaluate the trade-offs in performance. According to a report from the International Wire & Cable Symposium, the right wire rope can improve overall project outcomes by as much as 20%, highlighting the importance of making informed decisions based on both cost and performance metrics. By doing your research and understanding the materials available, you can ensure that you are making budget-friendly choices without compromising on quality.

Cost vs. Performance of Stainless Steel Wire Ropes

This chart illustrates the balance between cost and performance for different types of stainless steel wire ropes commonly used in various projects. The cost is measured in dollars per meter, while performance is assessed based on tensile strength in kilonewtons (kN). This information can help you make budget-friendly choices.

Related Posts

-

2025 Top Stainless Steel Cable Uses Benefits and Buying Guide

-

Exploring Growth Opportunities for Stainless Steel Cable Railing Systems at the 138th Canton Fair 2025

-

Why Choose Stainless Mesh for Your Next Project? Key Benefits Explained

-

The Science Behind Stainless Mesh and Its Impact on Modern Industries

-

Exploring Cable Railing Innovations at the 138th Canton Fair 2025 in China

-

Transform Your Space with Stylish Cable Railing Kits for Modern Home Designs