Best Stainless Cable Options for Your Projects?

In the construction and manufacturing industries, choosing the right materials is crucial. Stainless cables are often preferred for their durability and resistance to corrosion. According to John Smith, a renowned expert in the stainless cable industry, “The right stainless cable can make or break a project.” His words emphasize the significance of selecting quality stainless cables.

Many factors determine the best stainless cable options. These include tensile strength, flexibility, and resistance to environmental elements. While navigating through various options, it’s easy to feel overwhelmed. Choosing the wrong type can lead to project delays and increased costs.

Determining the right stainless cable means understanding needs better. Every project is unique, and not all stainless cables are created equal. Some might wonder: How do I ensure my choice is suitable? Reflecting on specific project requirements can guide decision-making. Mixing different types may seem tempting but often leads to complications. As we delve into the best stainless cable options, it is vital to weigh both benefits and potential drawbacks.

Understanding Stainless Steel Cable: Types and Properties

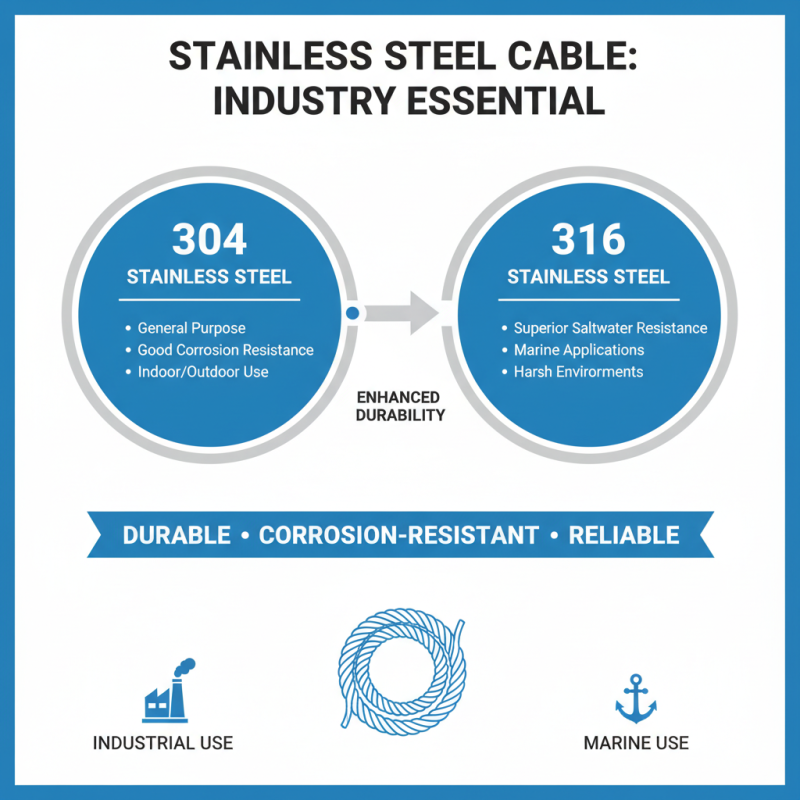

Stainless steel cable is essential in various industries. Its durability and resistance to corrosion make it a favorite choice. Generally, two main types exist: 304 and 316 stainless steel cables. The 304 variant suits most general purposes. However, 316 offers superior resistance to saltwater. This quality is crucial for marine applications.

According to industry reports, the global stainless steel cable market is projected to grow by 6% annually until 2028. This growth reflects its widespread use in construction, automotive, and industrial sectors. For example, construction projects often use 316 cables for suspending structures. The cost-efficiency of these cables plays a vital role in project budgeting. Yet, despite their benefits, issues like tensile strength variability exist. This inconsistency can lead to potential project failures if not addressed.

Environment plays a significant role in cable longevity. While stainless steel resists rust, harsh conditions can lead to wear over time. Regular inspections are necessary. They reveal hidden issues that could escalate into bigger problems. Understanding these factors is crucial for successful project outcomes.

Factors to Consider When Choosing Stainless Steel Cables

When selecting stainless steel cables, several factors come into play. The environment is crucial. Will the cables be used outdoors or in humid conditions? Corrosion resistance is paramount. Verify the grade of stainless steel. 316 stainless offers superior protection against harsh elements, while 304 is suitable for less demanding settings.

Tip: Always test a small length in your intended environment. Look for signs of wear or corrosion. This simple check can save time and money later.

Consider the cable diameter necessary for your project. Thicker cables provide more strength but can be heavier and costlier. Conversely, thinner cables are lighter but may not withstand heavy loads. Finding the right balance is essential.

Tip: If unsure about the diameter, consult with professionals who can offer guidance. Their experience can help you avoid mistakes. Reflect on past projects. Have thicker cables ever been too much? Did thinner cables fail? Such insights can guide your current choice.

Common Applications of Stainless Steel Cables in Various Projects

Stainless steel cables are versatile and durable, making them ideal for various projects. They are commonly used in construction for handrails and support systems. Their corrosion resistance allows for outdoor applications, especially near water. These cables add safety and aesthetic appeal.

In landscaping, stainless steel cables support planting structures and trellises. They provide a modern touch to garden designs. Additionally, they are often used in art installations. Artistic structures can incorporate cables for both stability and visual interest. However, the tension must be managed carefully to avoid sagging.

Despite their benefits, not all projects need stainless steel cables. Some applications may benefit from alternative materials. Cost can be a factor too; stainless steel is often more expensive. It’s crucial to evaluate each project’s specific requirements. This reflection can lead to better material choices.

Comparing Different Grades of Stainless Steel for Cable Use

When selecting stainless steel cables for projects, understanding the various grades is crucial. Grade 304 is often the go-to choice. This grade offers good corrosion resistance and weldability. It performs well in many applications, particularly in marine environments. However, some users report that it can be susceptible to pitting in harsh conditions.

On the other hand, Grade 316 stainless steel is often recommended for more demanding situations. Its molybdenum content gives it enhanced resistance to corrosion, especially in saltwater. Industry reports indicate that 316 cables endure significantly better when exposed to corrosive environments than 304 cables. Many maritime and industrial applications rely on its durability.

However, it’s essential to acknowledge that 316 stainless steel can be more expensive than 304. This cost may deter some projects. Additionally, users might sometimes overlook the importance of proper care. Regular maintenance, such as cleaning, can prolong the lifespan of both grades. Balancing cost and performance is vital for the best outcomes.

Best Stainless Cable Options for Your Projects

| Grade | Corrosion Resistance | Tensile Strength (MPa) | Typical Uses |

|---|---|---|---|

| 304 | Good | 515 | Architectural, Food Processing |

| 316 | Excellent | 580 | Marine Applications, Chemical Processing |

| 321 | Good | 515 | High-Temperature Applications |

| 410 | Moderate | 500 | Cutlery, Kitchen Equipment |

| 430 | Fair | 480 | Appliances, Automotive Trim |

Maintenance Tips to Ensure Longevity of Stainless Steel Cables

Stainless steel cables are popular in various projects. However, proper maintenance is essential for their longevity. Regular inspections can help spot any rust or wear. Look for signs of corrosion and fraying. Addressing these issues early can prevent larger problems later.

Cleaning stainless steel cables is crucial. Use mild soap and warm water for routine cleaning. Avoid harsh chemicals that can damage the surface. Dry the cables thoroughly after cleaning. This simple step helps prevent moisture buildup, which can lead to rust. If there's heavy grime, consider using a soft brush.

Storage also plays a significant role in cable longevity. Store cables in a dry, cool place. Avoid exposing them to extreme temperatures. Keeping them in a protective cover can guard against dust and debris. It’s easy to overlook these details. Yet, they can make a big difference over time. Reflection on maintenance practices can enhance the lifespan of your cables.

Related Posts

-

2025 Top Stainless Steel Cable Uses Benefits and Buying Guide

-

Top Uses and Benefits of Stainless Cable in Various Industries

-

Top 10 Cable Railing Systems for Decks You Need to Consider?

-

Why Metal Cable Railings are the Future of Modern Outdoor Design: A Comprehensive Guide

-

10 Reasons Why Steel Cable Railing is the Best Choice for Modern Decks: Safety, Durability & Style Insights

-

Understanding the Lifespan and Maintenance of Wire Rope for Optimal Performance and Safety