2026 Top Stainless Mesh Innovations for Industrial Applications?

The world of industrial applications is constantly evolving. Stainless mesh has been at the forefront of this innovation. Its versatility makes it a popular choice across various sectors. In 2026, new trends in stainless mesh are emerging. These innovations promise enhanced durability and efficiency.

Manufacturers are developing lighter and stronger stainless mesh options. This will reduce material costs and increase performance. Many industries, such as food processing and construction, benefit from these advancements. The need for fine filtration and strength is critical. What makes this exciting is the potential for custom solutions tailored to specific needs.

Yet, it’s important to reflect on the challenges. Not every stainless mesh product meets the highest standards. Quality control can be inconsistent. Buyers must remain vigilant when selecting materials. This evolving landscape requires continuous learning and adaptation. Keeping pace with these changes is vital for success.

Latest Trends in Stainless Mesh Design for Industrial Use

In recent years, the stainless mesh design for industrial applications has evolved significantly. A report by Global Market Insights indicates a projected growth of 5.4% in the stainless steel mesh market by 2026. This trend highlights the increasing reliance on stainless mesh across various sectors. Industries ranging from automotive to aerospace require durable and corrosion-resistant materials.

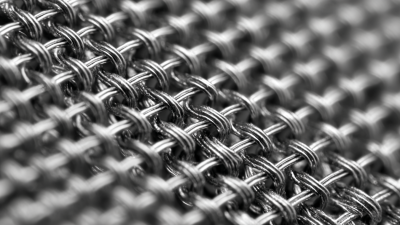

Innovations such as advanced weaving techniques have emerged. These techniques enhance the mesh's strength while maintaining flexibility. For instance, finer mesh sizes can filter smaller particles without sacrificing airflow. A study published in the Journal of Materials Science found that optimally designed meshes improved filtration efficiency by over 30%. However, challenges remain. Some designs struggle with durability over extended use.

Sustainable practices are also gaining traction. Manufacturers are sourcing recycled materials for mesh production. This approach is not only eco-friendly but also cost-effective. Yet, the balance between quality and sustainability is delicate. As innovation progresses, the industry must address these inconsistencies. Feedback from manufacturing teams can drive improvements. This reflects a growing need for collaboration in mesh design innovation.

Advancements in Stainless Steel Mesh Manufacturing Techniques

The advancements in stainless steel mesh manufacturing techniques are pivotal for industrial applications. Recent reports highlight a 15% growth in demand for stainless mesh in sectors like food processing and pharmaceuticals. Enhanced production methods drive this surge, enabling the creation of finer and more durable mesh. Companies are exploring 3D printing and laser cutting technologies, which result in complex designs that reduce material waste. However, the industry faces challenges, including the high initial costs of these technologies.

Another area worth noting is the development of corrosion-resistant coatings. These innovations extend the lifespan of stainless steel mesh but can complicate recycling efforts. Reports indicate that 40% of companies have yet to adopt these advanced techniques. Education and resources are needed to bridge this gap. Moreover, while precision engineering ensures quality, inconsistent results still plague some manufacturers. The focus should be on refining these processes to foster a more reliable output for various industrial needs.

Key Applications of Stainless Mesh in Various Industries

Stainless mesh has seen remarkable growth across various industries. Its applications range from aerospace to food processing. According to a recent report, the industrial wire mesh market is projected to reach $3.5 billion by 2026, highlighting the undeniable demand for durable materials.

In the food industry, stainless mesh offers benefits like durability and corrosion resistance. It ensures safety and hygiene, making it ideal for filtration applications. Protective barriers made from stainless mesh also reduce contamination risks.

**Tips:** When selecting stainless mesh, consider the specific requirements. Is it for filtration or safety? Each application requires different mesh specifications.

In the construction sector, stainless mesh provides structural support and corrosion resistance. It is crucial for reinforcing concrete. However, quality can vary significantly across suppliers. Always assess material quality before making decisions.

**Tips:** Regularly review your supplier’s performance. A reliable source ensures consistency in strength and durability.

Innovative Coatings and Treatments for Enhanced Mesh Performance

Innovative coatings and treatments are crucial for enhancing the performance of stainless mesh in industrial applications. Recent advancements focus on improving durability and resistance against various environmental factors. These new coatings can significantly increase the lifespan of the mesh. For example, applying specialized polymers can reduce corrosion caused by harsh chemicals.

Some treatments enhance the mesh's ability to withstand heat and fatigue. For instance, thermal barrier coatings can help in high-temperature environments. This innovation is essential for industries like aerospace and automotive. However, these processes can be complex and costly. Not every manufacturer might find them feasible.

As industries adapt to new technologies, the need for better mesh is evident. Innovations aim to address challenges such as wear and tear. Yet, there are still unanswered questions about long-term effectiveness. Many users may wonder if the initial investment is worth the potential gains. Balancing performance improvements with costs remains a challenge in this field.

2026 Top Stainless Mesh Innovations for Industrial Applications

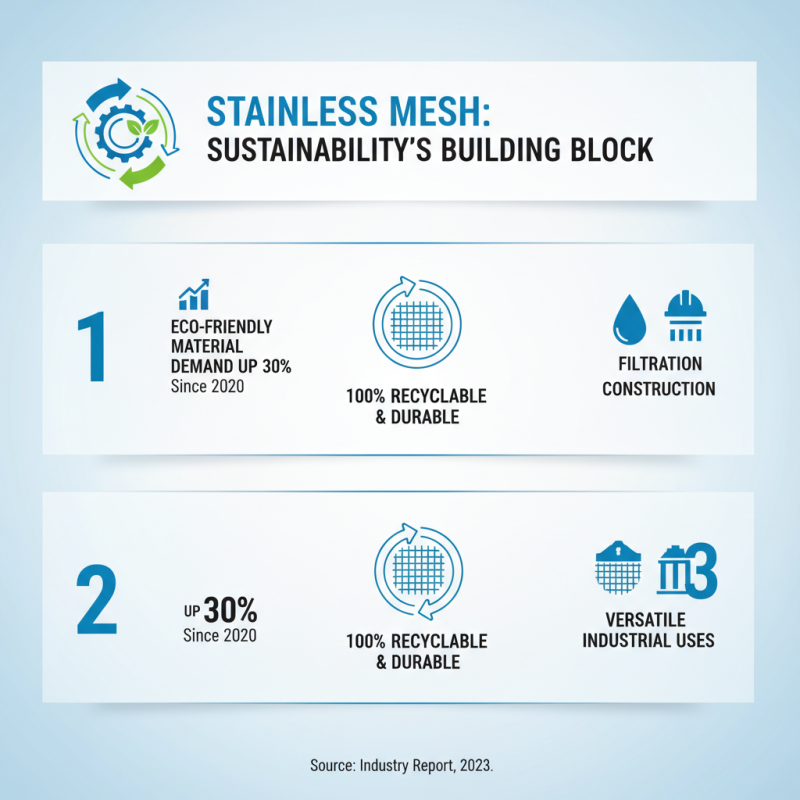

Future Outlook: The Role of Stainless Mesh in Sustainable Industries

The role of stainless mesh in sustainable industries is becoming increasingly vital. According to a recent industry report, the demand for eco-friendly materials has surged by 30% since 2020. Stainless mesh is not only recyclable but also highly durable, which contributes to its growing popularity in various sectors like filtration and construction.

Stainless mesh solutions offer excellent resistance to corrosion. This property ensures longevity in harsh environments. However, the manufacturing process of stainless steel can be energy-intensive. There is an ongoing discussion about finding more sustainable sourcing and production methods. A shift towards renewable energy in production could potentially lower carbon footprints.

Additionally, stainless mesh plays a crucial role in filtration systems for water treatment. These systems are critical as global water scarcity impacts millions. Some reports indicate that innovative designs in stainless mesh can enhance filtration efficiency by up to 40%. However, ongoing innovation and investment in research are essential to fully realize these potential benefits and address production challenges.

Related Posts

-

The Science Behind Stainless Mesh and Its Impact on Modern Industries

-

Why Choose Stainless Mesh for Your Next Project? Key Benefits Explained

-

How to Choose the Right Steel Cable for Your Project Needs

-

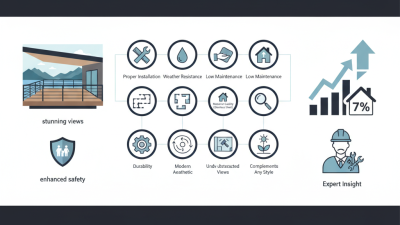

Top 10 Cable Railing Tips for a Stunning and Safe Deck or Balcony Design

-

Top 10 Benefits of SS Cable Railing for Modern Home Designs

-

The Ultimate Guide to Choosing the Right Cable Stair Railing for Your Home Decor